Harnessing the Power of Finite Element Analysis

Part 2: Structural Analysis

By Amin Moghaddas

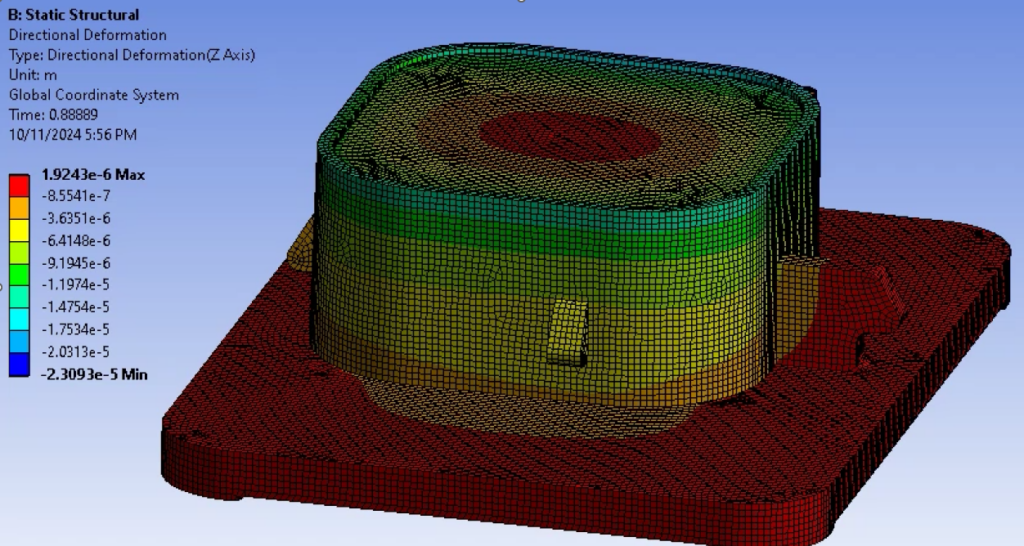

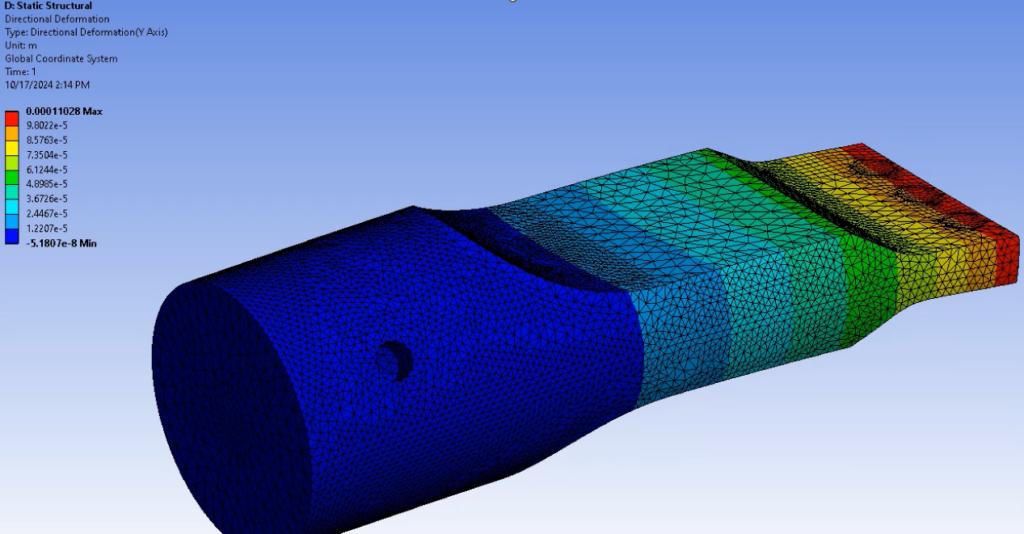

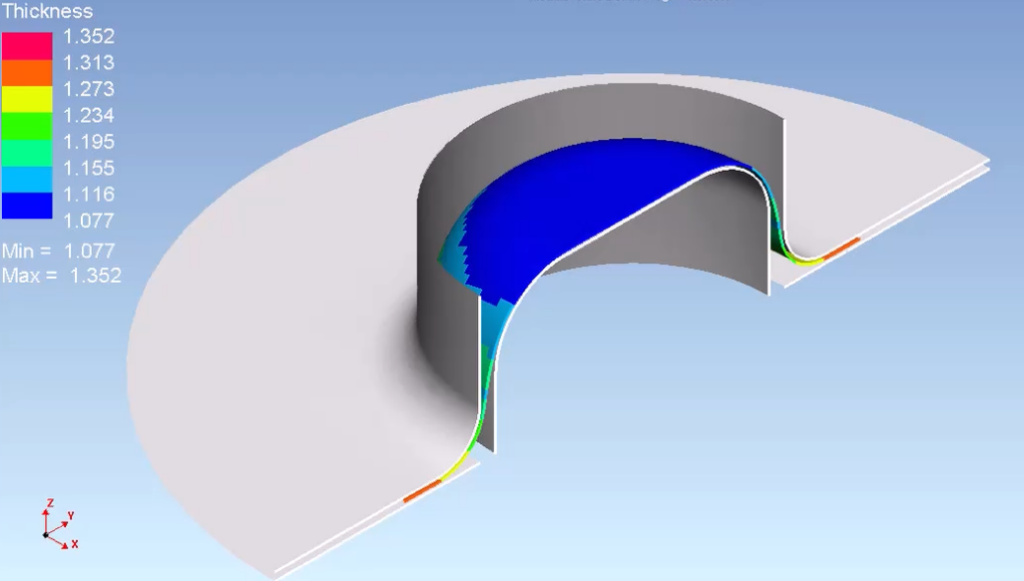

Structural analysis is a critical component of Finite Element Analysis (FEA) that focuses on assessing the performance of structures under various loads and conditions. It allows engineers to refine designs, reduce material usage, and enhance performance while minimizing the need for costly physical prototypes.

during ultrasonic metal welding

Structural analysis is especially useful in industries such as automotive, and aerospace, where it addresses complex geometries and material behaviors, ensuring reliable and efficient designs. By simulating real-world scenarios, we can predict potential failure points and optimize designs for safety and durability.

At EWI, our expertise not only ensures that your projects are functional and resilient but also helps you save time and resources by using FEA to Identify any issues in designs before manufacturing. If you’re interested shortening the product development time while reducing testing and redesign costs, please contact [email protected] to discuss how we can use our FEA tools to assist you!

To read the first article in this series, click here.

Amin Moghaddas is an Applications Engineer in the EWI resistance and solid-state group with more than 15 years of expertise in Finite Element Analysis (FEA). His primary focus is computational modeling of thermal processes, specializing in predicting temperature profile, residual stress, and distortion. Amin also has deep expertise in vibration analysis, designing and fabricating tooling for ultrasonic systems. Additionally, he is highly skilled in the structural analysis of components, including both static and dynamic simulations.