EWI has capability in high productivity strip cladding. If you desire an increase in productivity, strip cladding may be a solution for you. There are two variations of strip cladding, submerged arc and electroslag. Electroslag strip cladding (ESC) can achieve deposition rates of over 75-pounds-per-hour when using a 60-mm wide strip. Compare this to submerged arc welding (SAW) at about 25-pounds-per-hour and tandem-SAW at just over 40-pounds-per-hour.

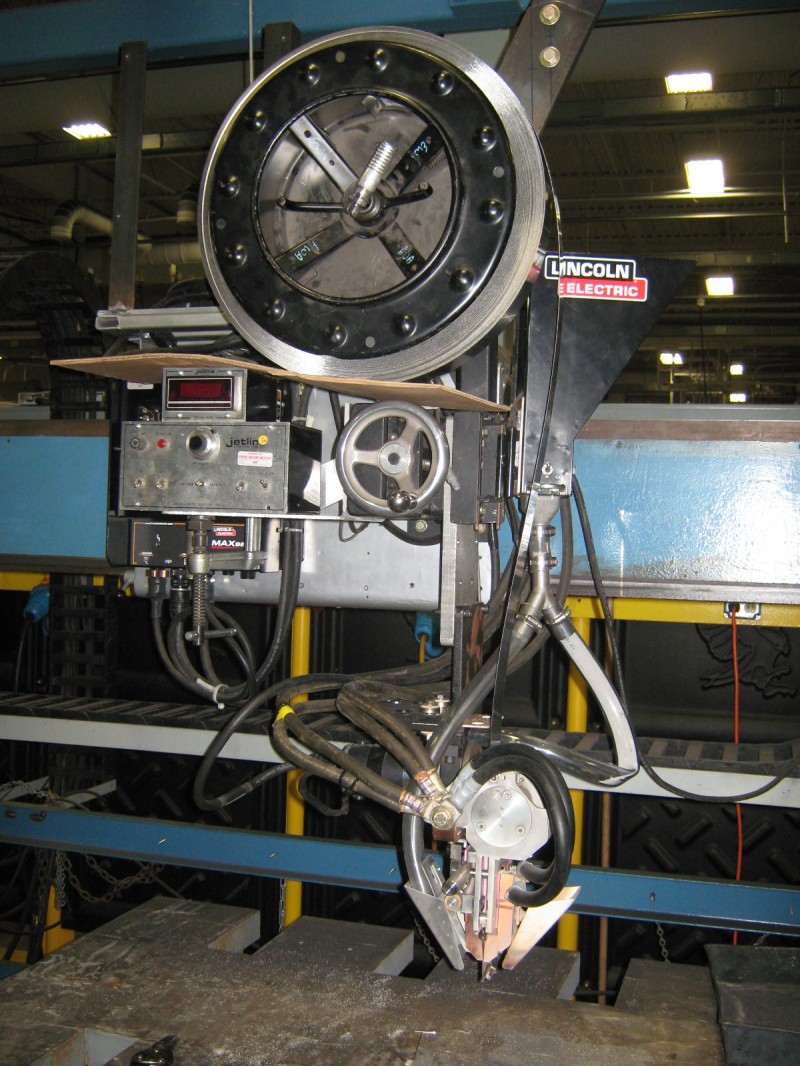

The equipment at EWI consists of a Bohler strip feeding head capable of feeding 30-mm or 60-mm strip and two Lincoln Electric AC/DC 1000 machines in parallel to deliver a total of 2000-amps.

If you have an application that may be suitable for strip cladding, and you would like to investigate the possibility, please contact EWI at [email protected] or click here.

Video of process operating at 48-lbs/hr deposition rate:

Video of finished weld: