This is a reprint from one of our Insights newsletters from years ago, and it really stands the test of time…

We see it much too frequently, but most often in the summer. That’s when production line changeovers and new products are launched. That’s when deficiencies in the manufacturing process are showcased. That’s when we receive the most desperate calls for assistance with the “welding” process. As eager as we are to help, that’s when the opportunity to improve the situation is nearing its lowest point.

The pressures and constraints of product launch often create nearly impossible circumstances to make substantial changes to methods and procedures in the manufacturing process. The opportunities for optimizing productivity and quality have already been lost.

How do manufacturing efforts arrive at this unfortunate condition; and why does welding so often seem to be the focus of the problem? Welding brings individual components together in an assembly that represents some stage of completion for the product.

Until the joining step is executed, the validity of the prior actions may not be known. These prior manufacturing steps usually do not demonstrate their correctness with the same clarity that joining does.

Accepting that the joining community will likely continue to experience that spotlight, how can we help it be a more favorable one? How can the joining community provide the best inputs to productivity and quality? By involving EWI early.

Even though the welding step may occur near the end of a manufacturing sequence, it should not be considered last in the product and process design and planning phases.

Every decision in the planning phase limits the options in the manufacturing phase. If the planning decisions do not take joining capabilities and limitations into consideration, the manufacturing solution cannot be optimized.

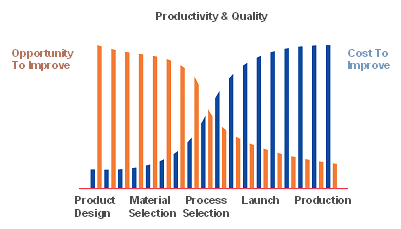

Doesn’t it cost more to include EWI’s materials joining engineering into the design effort? Absolutely not! Not in the short run and certainly not in the long run (above left figure). Even in the early product design phases, EWI can help focus the efforts of designers and avoid unnecessary exploratory activities. When critical joining process questions arise, EWI can provide unbiased input, welding feasibility analysis, and a bridge to the production community within the member organization.

The efficiency and effectiveness of EWI’s involvement are at their highest in the early stages of a product cycle. Perhaps our most effective technique for providing this assistance is a design/process review visit to EWI, a service that is included in EWI membership. The synergy between EWI’s engineers and the member company’s engineers yields an incalculable benefit. Unfortunately, we hear all too often, “I wish we’d come here sooner.” It’s never too early to ask EWI to help.

Learn more about EWI at www.ewi.org, on Twitter @EWI_innovation, and Facebook https://www.facebook.com/ewiinnovation.