Advancing Polymer Weld Analysis to Prevent Fatigue Failures

At EWI, we always strive to solve the most pressing manufacturing challenges. We’re excited to announce the launch of a groundbreaking research initiative that focuses on a critical issue in polymer welding — identifying the relationship between intermolecular diffusion and fatigue failures using Heated After Cross-Section (HACS) analysis.

The Challenge We’re Tackling

Polymer welding plays a vital role in the manufacture of numerous products, impacting everything from automotive components to medical devices to consumer products. In a polymer weld, the molecular chains of the polymer diffuse across the interface, creating a strong bond. However, when this diffusion does not occur, an adhesive bond is formed instead of a true weld. While adhesive bonds may perform similarly to welds under standard mechanical and leak testing, they are more susceptible to fatigue, which can result in unexpected product failures during use. Examples of product failure due to lack of diffusion that we have seen include:

- Gas tank for power tools – leaking during customer use, which is a significant safety hazard

- Coolant tank for an automotive engine – potential major recall issue

- Filter for medical equipment – failure caused a delay in treatment, which can be life threatening

Without a reliable method to identify if diffusion has occurred, manufacturers risk safety hazards, costly recalls, operational disruptions, and even potential litigation.

The Research

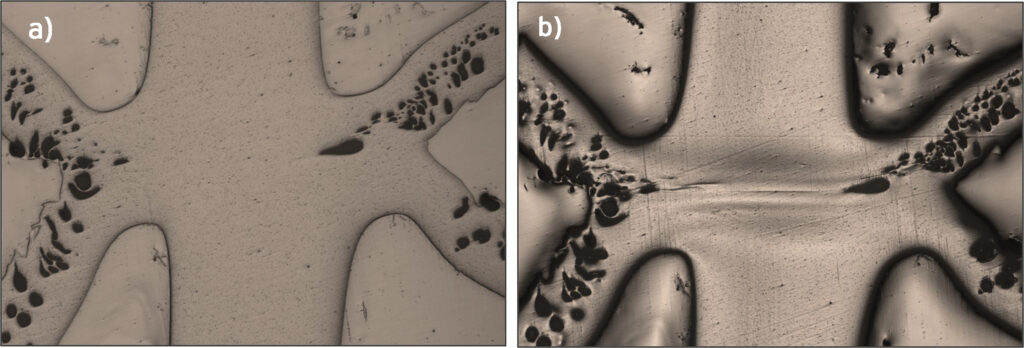

A failure to accomplish diffusion in a polymer weld can be catastrophic for manufacturers, and the only method with the potential to identify whether diffusion has occurred is the HACS analysis. However, there has been no established quantitative research done to show the relationship between diffusion, as observed through HACS, and fatigue analysis.

This IRD project aims to establish a clear link between diffusion and fatigue resistance in polymer welds using the HACS analysis. By providing dedicated resources, EWI will be able to generate a pool of data to support the theoretical basis of why the HACS process is so powerful for weld analysis.

What’s Next

Polymers are increasingly being used in more complex applications, and as a result, the need for more precise quality evaluation methods has never been greater. Industries like automotive, medical, and consumer products are all pushing the boundaries of polymer technology, and as these technologies evolve, so must our ability to test and ensure their integrity.

Stay tuned for future updates, and as always, feel free to reach out to our team if you’d like to learn more or discuss how this research could impact your products and processes.