In most every solar module, regardless of technology, there are interconnections between the collectors and the leads conveying power out of the module. Most of my experience is with PV and C-PV modules.

This is a photo of a silicon-based solar array near my home. Of note in this view are the lead wires and junction boxes. The leads are stranded copper wire, chosen for its high electrical conductivity and low resistance. Stranded wire is used, since with a tough rubberized insulation, it will remain flexible in all but the coldest environments. Joining of the collectors and ground busses of the cells (in multi-cell modules) or the buss leads in single-cell modules, requires some sort of joining operation.

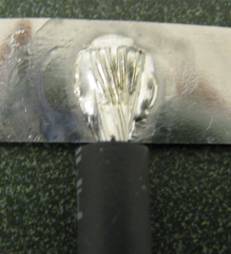

Joining to the lead wires is usually accomplished by soldering, since the joint design is a stranded copper wire to a foil. Soldering is the favorite process since it adds a filler material to help the transition in geometry. Also, usually there is only access from one side, and squeezing and welding the parts with ultrasonic or resistance welding is not possible. A typical solder joint between a lead wire and buss foil is shown below:

Some junction boxes have flat copper leads ready to join to the buss. In these cases, the parts must be tin or solder plated for soldering to the buss strip. Depending on the space allowed for access, parallel gap resistance welding might be possible. Although the heat generated will be higher, the welding time will be much shorter (~30ms compared to 2-5 seconds for soldering).

Most C-PV cells are on a silicon substrate, or something similar. For these cases, a plating or metal coating must be applied to allow for joining of leads. Preferred coatings are silver, gold, nickel, or tin. Tin platings can be soldered, while the other can be soldered or welded with parallel gap resistance welding. Ultrasonic wire and ribbon bonding can also be used, and is preferred in many cases since copper and aluminum wire and ribbon can be used.

C-PV cells must be manufactured with contacts that can be welded. The adhesion of these coatings is important, as well as the width and thickness, to ensure good current-carrying behavior. For this reason, it is important to know the joining process that will be used for module manufacturing when designing the cells.

Next time I’ll get into more details about the various joining processes, and discuss design considerations for each of them.