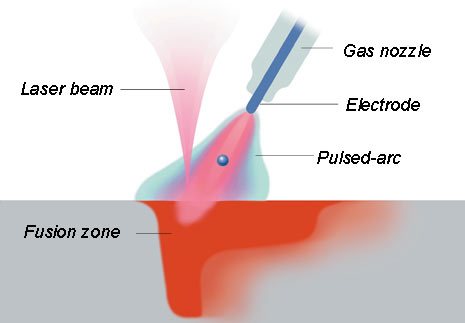

The EWI Nuclear Fabrication Consortium (NFC) has recently begun work on a U.S. DOE sponsored project that will demonstrate the advantages of using the hybrid-laser-arc-weld (HLAW) process on nuclear grades of nickel-based materials. The HLAW welding process combines the advantages of the LBW and GMAW welding processes, to produce deep penetrating welds at very high travel speeds. Check out the simple schematic of the HLAW process below (courtesy of HLAW equipment manufacturer Fronius).

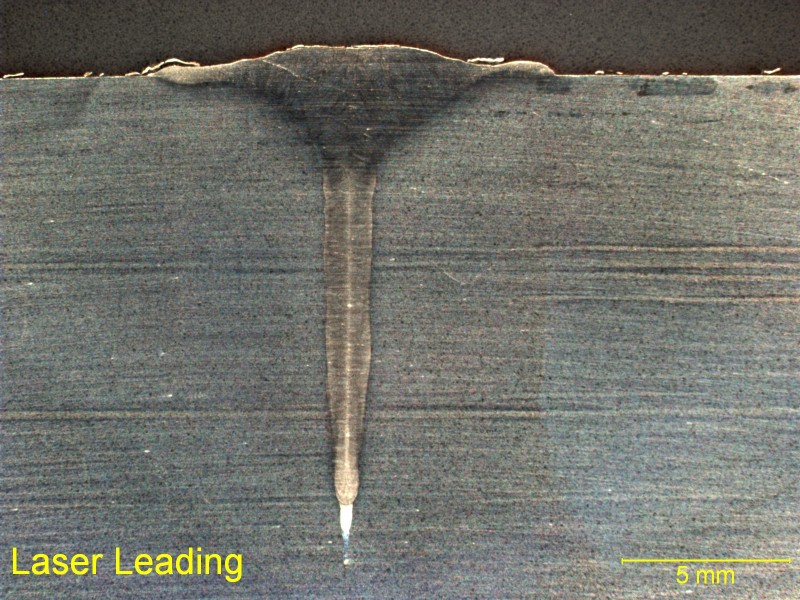

Currently, the primary advantage envisioned for using the HLAW process will be the deposition of extremely deep root passes, thereby dramatically reducing the overall weld-time on thick-section welds. An additional advantage should be the reduction of residual stresses at the weld root, which would be advantageous for the stress-corrosion-cracking (SCC) resistance of these welds. Check out the picture below of an initial bead-on-plate weld on Inconel 690 using Filler Metal 52; a penetration depth of approximately 15mm has been achieved. If you have any questions regarding the HLAW process, or the current DOE project, please contact Morgan Gallagher at +1-614-688-5134 or at [email protected].