Lightweighting is an important focus for design folks in the automotive and aerospace worlds. Reducing the weight of a vehicle helps to improve fuel economy and reducing the weight of an airplane additionally enables more cargo to be carried. Magnesium-Aluminum-Zinc (Mg-Al-Zn) alloys have the highest strength to weight ratios of structural metals. AZ31B (Mg-3Al-1Zn) is 35-percent less dense than aluminum, but has 89-percent of the strength of 6061-T6 aluminum.

One of the challenges when trying to join Mg is that it rapidly oxidizes at temperatures above 400-degrees Celcius as the image below shows.

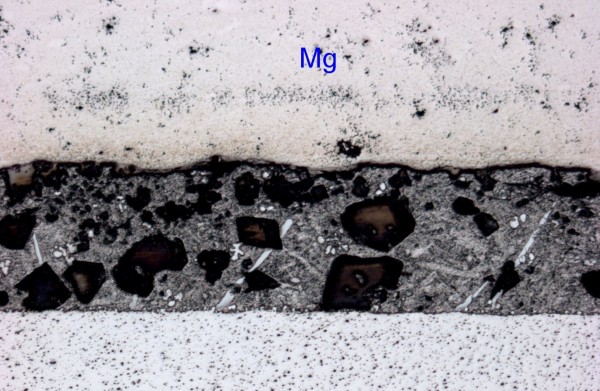

Through our unique soldering approach, EWI has been able to join Mg to both aluminum and steel with very limited oxidation.

Shown below are cross sections of a Mg to steel joint. The first one is shown with no magnification and the second shows the bond line at 50x magnification.

Here are the cross sections of a Mg to Al joint. The first one is shown with no magnification and the second shows the bond line at 50x magnification.

If you would like more information on joining solutions for lightweighting, or dissimilar metals joining, please contact EWI at [email protected] or click here.

Thanks for your interest in EWI.