One of the great things about working as a welding engineer is that since the discipline is so young, there is still a lot of room for innovation. Relatively speaking, many welding technologies are still in their infancy, so innovation is often par for the course. Since coming up with the “next greatest thing” is so exciting, the tendency can be to overlook “lower-tech” solutions, even when they can have a significant impact at a relatively low cost. While hybrid/adaptive/remote/laser/ultrasonic-assisted/friction-stir welding may be the next greatest thing, not everyone needs it – and not everyone can afford it.

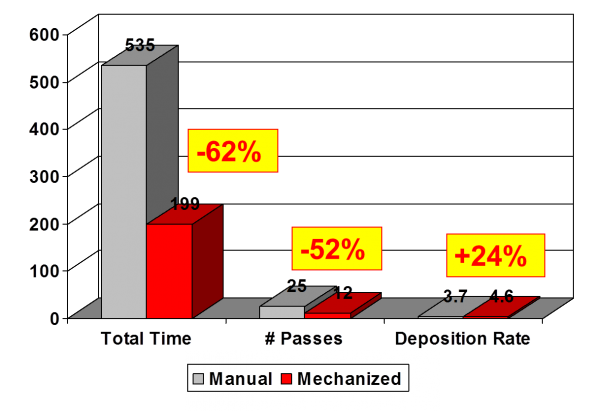

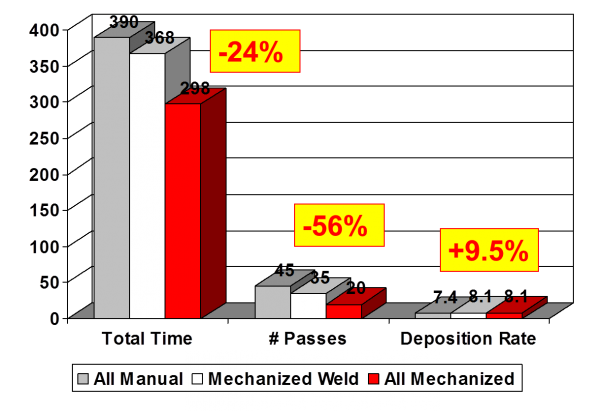

A great example of a low-tech, high-impact solution is work completed by EWI’s Steve Massey looking into the mechanization of short welds on T-joints, with a maximum length of 5 feet. A common belief is that for mechanization to be worth-while, the weld must be very long, causing many manufacturers to dismiss mechanization as “not worth the hassle.” In addition to mechanized welding, mechanized backgouging was also investigated. A tractor set-up was used and time studies were conducted for backgouging and welding in the horizontal (2F) and vertical (3F) positions. Results for vertical and horizontal trials are provided in Figures 1 and 2, respectively.

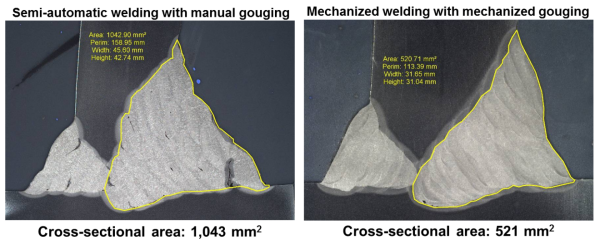

Figure 3 provides a visual comparison of two joints completed in the vertical (3F) position. Note that the macros are not the same scale and the second-side area in the case of manual gouging is double that of mechanized gouging.

While a wide variety of mechanization equipment is commercially available, challenging applications may require modifications or additions to existing equipment. This can often allow the use of mechanization for applications which have historically been welded manually or semi-automatically due to access issues or part complexity. EWI’s Designers have significant experience in the design and modification of mechanized equipment for challenging welding applications.

For more information on this topic please contact Marc Purslow ([email protected], 614.688.5150) or Steve Massey ([email protected], 614.688.5251).