The additive manufacturing (AM) process laser powder bed fusion (L-PBF) is applied frequently to build complex, shaped parts. The process uses a laser beam to melt metallic powders which are then deposited layer by layer. As the range of metals and alloys for L-PBF continues to expand, the characteristics of these new materials need to be evaluated for strength and viability. One such material is nickel-based superalloy Inconel® 718, an excellent choice for L-PBF due to its superior performance at high temperatures.

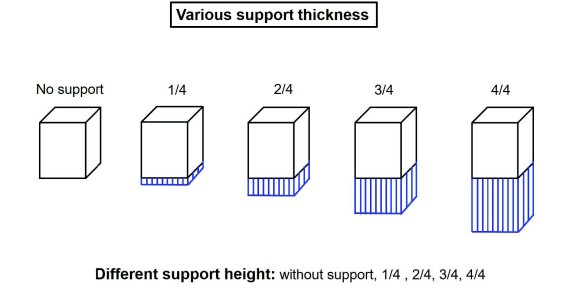

EWI Project Engineer Hyeyun Song has written a new paper, Microstructural Evolution in IN718 Produced by L-PBF Additive Manufacturing, which describes EWI’s recent examination of the effect of varying support structure height on the local microstructural evolution in IN718 builds fabricated using L-PBF. This paper discusses the findings of this study.

To download this paper, click here now.

To learn about EWI’s technology development activities in AM, contact [email protected] or 614.688.5152.