Efficiently handling high laser power with custom optics is no new task for the EWI laser team. As our lasers continue to grow in power, so does the need for optics that can handle those power levels with minimal thermal distortion. Working with member company II-VI, Inc., we designed our third high power optical solution which is currently in the fabrication phase and due to be tested early this year. We will surely present the results at 2015 laser conferences.

Beginning back in 2007 with the purchase of a 10kW IPG Fiber laser, focal shift in commercially available optics presented a difficult challenge to completion of long welds. Standard transmissive optics simply could not handle the growing power available from laser manufacturers. As EWI continues to push the envelope with new applications, the need for stability and reliability are crucial to successful outcomes.

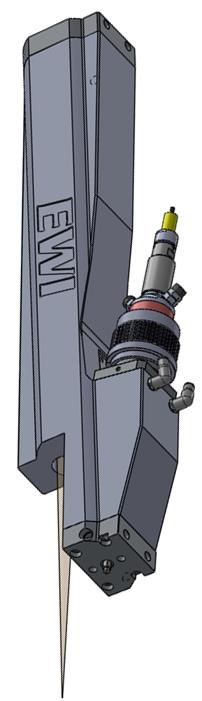

Through research and extensive testing EWI determined that transmissive optics were the primary culprit of focal shift, regardless of cleanliness. EWI’s last design eliminated transmissive optics (including cover windows) and incorporated dual, off-axis, asymmetric asphere mirrors. In other words, the diverging light from the fiber end is taken directly to a 1:1 focus through a patented, small orifice, aero window. The cavity that houses the fiber end and first optic is pressurized with inert gas (flowing through the window) to keep the critical components clean. After the first focus, the lower power density diverging beam in captured again on a second asymmetric asphere and re-imaged onto the work. EWI’s optics consistently deliver less than 0.2mm/kW of focal shift, even on imperfect, USED optics. Options for the high power reflective focusing optics include focal lengths of 425-mm and 500mm which yield spot size magnifications of 1.4X and 2X, respectively. However, the head is scalable to meet other application requirements. This design drastically increases the optics distance from the violent welding process without sacrificing spot size. According to Stan Ream, inventor of this patented optic,

“This is a totally scalable concept.” “We’re now configuring it to be able to take on power higher than 20 kW by changing angles of the mirrors and altering some cooling techniques. This concept could be adapted to become a 100-kW laser welding focusing optic.”

More information can be found in an article by Stan Ream featured in The Fabricator: http://www.thefabricator.com/article/laserwelding/tough-optics-for-extreme-laser-welding

Fabrication is currently underway for a more robust, production-hardened, version of the high power reflective focusing optics. Version 2 will introduce a vertical head orientation, better optics protection*, a sleeker design, improved cooling, and reduced optical alignment sensitivity. Look for the results early this year!

*Current housing design allows for various adaptable components to be added to the body for optics protection and plume management. Components may be concentric about the beam or off-axis.