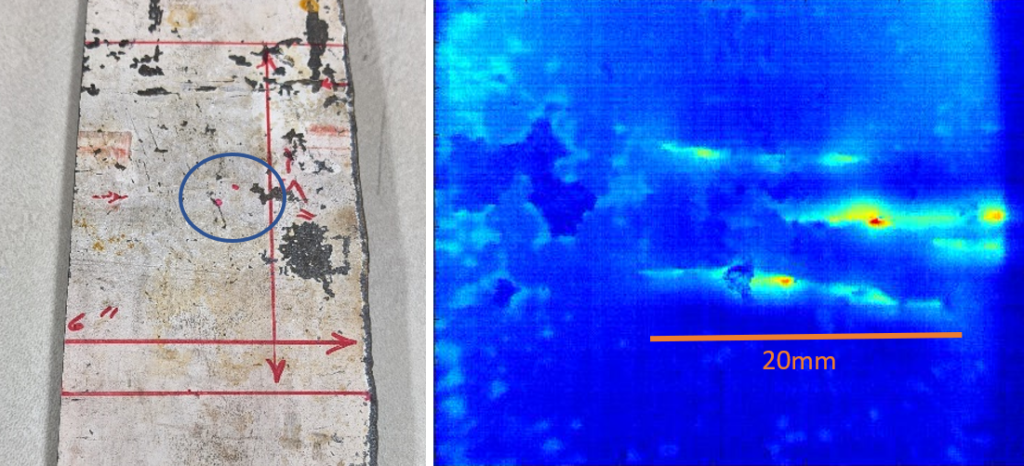

While conventional flash thermography is ideal for polymer materials, it can be challenging when used with metals due to reflectivity of the component. With pulsed eddy-current-assisted thermography (PECT), ferrous and non-ferrous steels, as well as titanium, can be inspected without surface reflection interference. Internal research on flattened, painted, and steel pipe is ongoing at EWI using various NDE methods to identify stress corrosion cracking. PECT has enabled the identification of such cracks in just a few seconds. Depth of crack can also be resolved with the thickness of the specimen known.

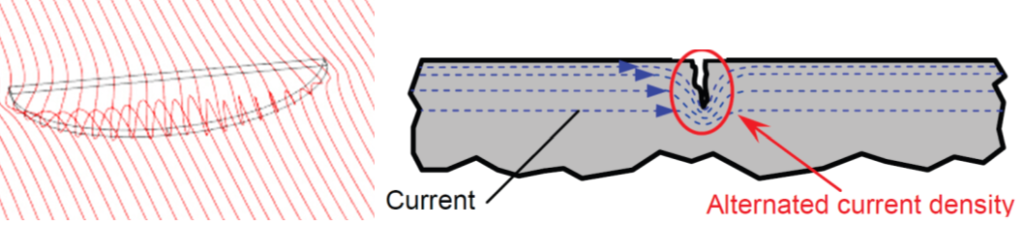

EWI now has in-house capability to use PECT to inspect surface breaking cracks due to weld defects and stress corrosion cracking. The PECT technique is enabled by using equivalent wave field transformation (EWFT) from diffusive propagation (in this case, thermal) for a 3D image of a component and its defects. Eddy currents introduced into the material by an induction coil interact with defects. In the case of a crack, eddy currents flow around the crack which can be observed by monitoring the effects of minimal heating diffusing through the thickness of the sample. Using the EWFT allows sizing of flaws including crack depth.

If you are interested in learning more about EWI’s work in non-contact thermography inspection, contact Lindsey Lindamood, Applications Engineer, at [email protected].