The idea that resistance and ultrasonic processes can be combined into an effective joining method has been around for more than 20 years, but has never been commercialized. With the increasing demand for lightweight materials in planes and vehicles, however, the resistance-and-ultrasonic concept is under reconsideration. Studies now indicate that this hybrid method could be a superior way to join high strength steels and high strength aluminums efficiently and safely.

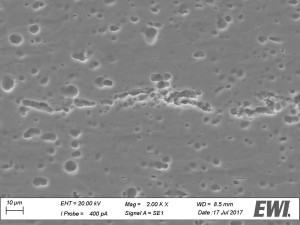

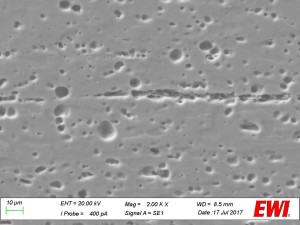

EWI recently completed a study comparing the hybrid process to ultrasonic metal welding, focusing on joining aluminum 6061 to itself. Using a prototype ultrasonic-resistive welding apparatus, the hybrid process achieved higher strength welds compared to ultrasonic welding alone. The results of this research are discussed in a new paper by Applications Engineer Lindsey Lindamood, Hybrid Ultrasonic Spot Welding of High Strength Materials.

Learn more about EWI’s joining capabilities.