As metal additive manufacturing (AM) processes become more frequent in manufacturing operations, a key component for acceptance is improved quality control methodologies. The current quality control paradigm does not include the ability to recognize quality throughout the build as it is barely scratching the surface of monitoring capability, let along control. EWI has begun performing research on in-process monitoring for AM, utilizing open architecture systems, an extensive library of sensors, and its welding engineering, controls and integration expertise.

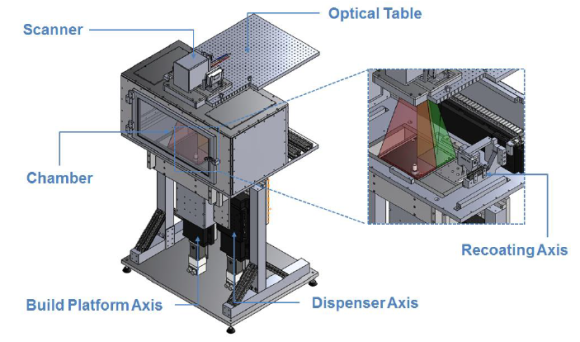

Many off-the-shelf options for sensing exist to provide real-time or quasi real-time quality information during the metal AM process. These include photodetectors and spectrometers for plume interrogation, infrared and visible spectrum imagers for the melt pool and the build area, surface topography generators including laser profilometers and three-dimensional macroscopes, and traditional nondestructive testing techniques including eddy current.

Each sensing technique exhibits its unique competencies and deficiencies in terms of total quality detection. Integration capabilities into commercial additive equipment very, as well. Understanding how disparate sensing techniques complement each other and optimization sensing techniques will be critical for the development of better quality control methodologies.

A new EWI paper by Paul Boulware, In-Process Monitoring Techniques for Laser Powder Bed Fusion, discusses the need for investigation and the factors that must be considered during development. This paper provides an overview of EWI’s work in evaluating different monitoring techniques and their applicability for inclusion in commercial L-PBF systems.

EWI Applications Engineer Paul Boulware, can be contacted at [email protected].