EWI has recently completed an internal research project on modeling of tensile residual stresses extending more than 5 weld widths from the weld joint.

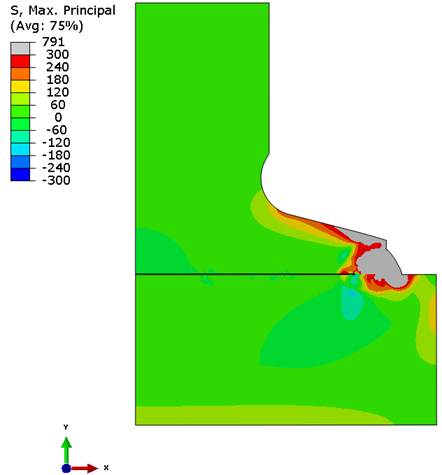

The finite element modeling showed that welding residual stresses could be high rather far away from a weld between two stiff steel components, compared to expectations embodied in API 579/ASME FFS-1. Modifying features of the 22-pass weld to change the local stresses at the weld did not do much to change the remote residual stresses out at a stress concentration region 5 weld widths from the weld zone. Changing how the pieces were fixtured did have an important effect on the remote stresses.

The work on this program is designed to be published and distributed to the industry to help modelers and users recognize cases where standard assumptions about the regions around welds with residual stress are violated. The paper and presentation from this work have been offered for the upcoming ASME Pressure Vessel and Piping Conference 2014. Other venues, such as Fabtech 2014, will also be considered.