As low-carbon energy options continue to evolve, EWI has been exploring related challenges including the qualification of new materials for hydrogen service, concerns related to legacy infrastructure conversion, and thermophysical modeling of impurity interactions. A year ago, we inaugurated our Environmental Testing Laboratory, focused on the evaluation of material properties under exposure to high-pressure, gaseous H2 environments. We are pleased to announce the expansion of the environmental testing capabilities with a second lab space dedicated to testing in CO2-rich settings.

“CO2 corrosion is an evolving area of study. The breadth of interactions between materials and complex CO2-rich environments is still not well understood,” says Josh James, Senior Technology Leader for Corrosion/Environmental Testing. “The emerging interest in CO2 transport for carbon capture, utilization, and storage (CCUS) has renewed the necessity for testing and evaluation capabilities that can address the foundational concerns of CO2 corrosion.”

In EWI’s new laboratory, test specimens are evaluated in various CO2-containing environments depending on the application. Currently, we are conducting immersion testing in CO2-saturated aqueous environments, exposure testing in dry/humid dense-phase CO2, and localized electrochemical parameter analysis focusing on effect of stress state on corrosion susceptibility. In the spring, we will expand to add noxious gaseous impurities like NOx, SOx, CO, and more to the scope of testable environments. According to Josh, “Our ability to establish and maintain precise control over test conditions is critical to ensuring accurate results.”

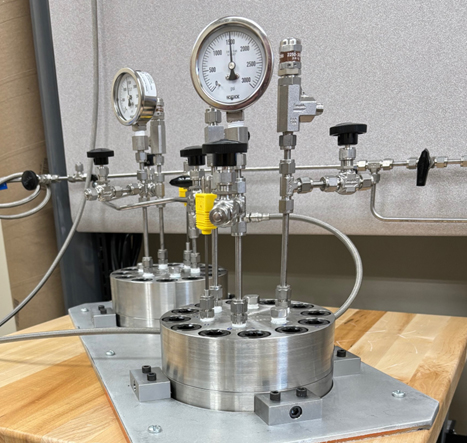

Pressure vessel setups capable of material evaluation in diverse, dense-phase CO2 compositions |

| The lab is equipped with Hastelloy pressure vessels and plumbing manifolds, a gas-metering system for establishing multi-impurity compositions, supercritical CO2 syringe pumps, multiplexed potentiostats (for high-throughput electrochemical parameter corrosion analysis), and an EWI-developed test cell for localized electrochemical analysis in CO2-rich environments. Do you have a need for testing in a high-CO2 environment? EWI can help. Contact Josh James at [email protected]. |