Arc-welding robots have been around for decades and are used in many industries, including heavy manufacturing, automotive, aerospace, and ship building. Historically, the knowledge and skill required to implement arc-welding robots has been substantial and may have discouraged first-time robot users. In recent years, however, robotic welding equipment manufacturers and integrators have advanced the level of control and ease of use.

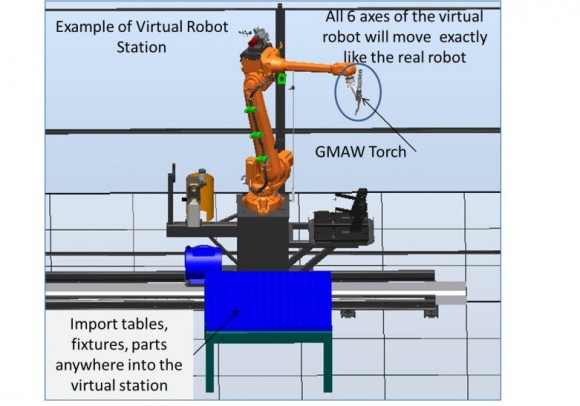

The development of offline programming (OLP) software has been one such advancement. By incorporating a 3D part model into the OLP software, which contains a model of the real equipment, the user has the ability to create a weld path without using the actual robot. Using a robot and a teach pendant to create a weld path can take hours, if not days, depending on the part size, configuration, or complexity. Using OLP can drastically reduce the programming time required and also eliminates the need to shut down production to program the robot.

Additionally, modern robotics systems that incorporate the use of OLP offer a variety of useful features to make implementation much easier. Some of these features include:

- Ability to perform reach studies

- Simulation videos

- Collision detection

- Cycle time estimation

- Multi-bead, multi-layer welds

- Searching joints to account for joint variations

- Calculated adaptive fill

If you are interested in learning more about the different offline programming options for robotic arc welding, please feel contact EWI at [email protected] or click here.

.