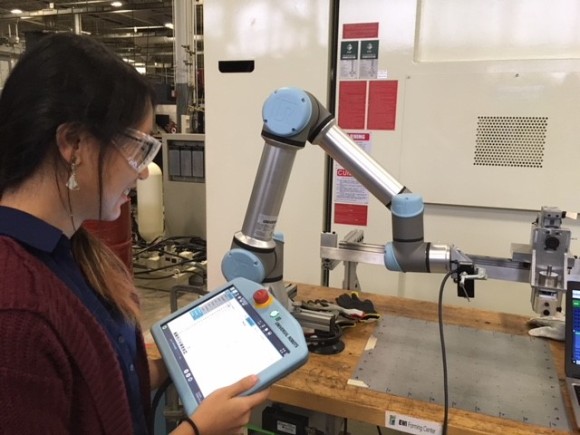

Recently, the EWI Ohio facility was pleasantly surprised with an opportunity to consign a cobot for a week. What I thought was going to be a 2-hour demo visit turned into a lovely, 5-day friendship with a UR5 robot. Initially, we set it up in an office cubicle because it was small, easy to program and let’s face it, kinda cute! Several colleagues came to see it because I had boasted about how easy it was to carry, program and use. But then, just like that visiting exchange student in junior high school, my new friend became WAY more popular than me. The next think I knew, it had booked a few jobs with different engineering groups, and then I never saw it again.

First, it went to the microjoining lab. Tim Frech needed some help with some small-scale resistance welds on thin sheet. No problem for the cobot. Tim was able to tell it what to do without any formal course in speaking ROBOT. Good job, little buddy (the cobot, not Tim)!

We are now working on a tele-welding application, and hope to make use of our new cobot friend when the project takes off. If you’d like to hear more about this or other remote automation innovations at EWI, contact me at [email protected] or 614.484.7600.

Connie Reichert LaMorte, Principal Engineer for Design, Controls & Automation, is a specialist in the areas of laser-based vision, control systems and adaptive welding.