EWI Forming Center Consortium

The EWI Forming Center Consortium (FCC), a member-based industry group, offers its partners opportunities for cross-industry technical exchange, joint research, and shared services.

Goals

The EWI Forming Center Consortium (FCC) brings together a diverse group of forming industry and research-based stakeholders from all over the world to advance the state of metal forming through organized and focused activities.

Identify the key challenges in forming technology and foster technical interchange to address those challenges

To fund and execute group sponsored pre-competitive research programs

To provide industry guidance through the results of the chosen projects

To use its programs to advance technical readiness in forming throughout manufacturing

Technical Focus

- Formability

- Lubricant Evaluation

- Forming Process Design

- Innovative Forming Technology

Current Projects

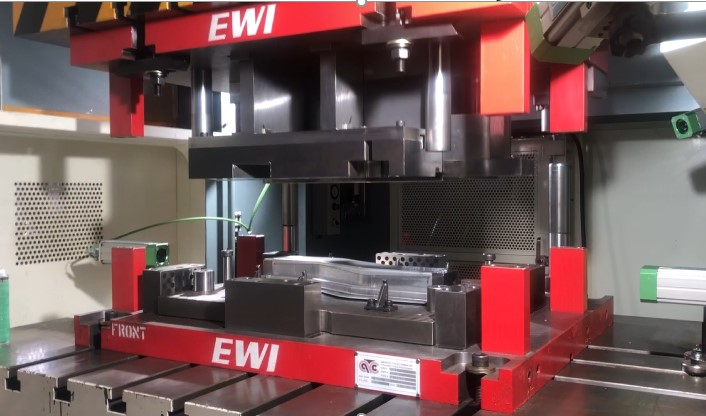

IMPROVEMENT OF THE MACHINE-LEARNING (ML) BASED CONTROL ALGORITHM FOR SPRINGBACK

To improve the smart forming control algorithm, this project is evaluating die friction variation and elastic deflection of tooling in addition to the variation of the incoming material properties using the 3MA NDT sensor. The project will demonstrate upgraded control algorithm with a 3MA NDT sensor, inline camera sensors, lubricant film thickness measurement sensor, and digital twin model to control springback of the S-rail parts for six different sheet materials including Gen3 steel and AA5xxx-6xxx effectively.

STAMPING EVALUATION OF LASER-WELDED BLANK MATERIALS

Three LWB materials of different steel grades and gauges are being studied to obtain the formability limits and the springback variation of the AHSS LWB in conditions near stamping production. The springback change with the LWB will be obtained in stamping with the S-rail tool. The project will deliver recommendations for the welded blank design to avoid weld cracking and early necking.

Completed Projects

FCC members have access to project results of all past projects. Recently included projects include:

- Real-time NDE-based Monitoring of Material Properties

- Intelligent Servo-controlled Forming Vehicle Structures

- Evaluating Lubricants and Tool Coatings for Warm Forming of Aluminum

- Automation Enhancement for the Intelligent Servo-controlled Forming Process

- Effect of Sheet Surface Finish on the Performance of Stamping Lubricants

- Intelligent Servo Forming for Springback Control

- Prediction of the Fracture in Forming of the Laser Welded Blank

Membership

EWI FCC members are invited to participate in annual member meetings in which project results are shared and reviewed. New projects are identified and selected at member meetings as well. Members are also encouraged to participate in project work groups which give guidance and direction during the execution of projects.

In addition to participation, FCC members have exclusive access to written results of current and previous FCC projects.

For more information about the EWI Forming Center Consortium, contact Laura Zoller at [email protected].

Looking to learn about EWI’s forming capabilities? Click here.

EWI Forming Center Consortium Membership

To learn more about membership and the benefits of the EWI Forming Center Consortium, contact Laura Zoller at [email protected].