It felt great to put the press release below on the wire today. In the world of materials joining, this is groudbreaking stuff… the kind of stuff that elevates the heart rates of everyone at EWI and has even our most subdued welding engineers, materials scientists, and industry experts dancing in the parking lot. (“Dancing” may not be the right word). Nonetheless, this is manufacturing technology innovation worth celebrating!

————————————————————————————————————–

EWI’s Silicon Carbide Joining Samples Survive MIT Nuclear Reactor Testing

New Technology May Solve Longtime Joining Challenge and Improve Reactor Safety

COLUMBUS, OH, August 28, 2012 – EWI, the innovation leader in materials joining and allied technologies, announced today that its silicon carbide (SiC) joining samples have emerged stable from six months of aggressive irradiation and water flow testing in the core of MIT’s research nuclear reactor in Cambridge, MA.

Silicon carbide fuel cladding is an emerging technology that has the potential for orders of magnitude increase in the safety of existing and future fleets of light water nuclear reactors. Transitioning from the current technology of zirconium alloy nuclear fuel cladding to a silicon carbide composite cladding is fundamentally a materials challenge, and it would represent the biggest shift in reactor materials technology since their original design and introduction.

For years, a major technical hurdle has been finding an economical solution for joining the end plug to the cladding tube after it has been loaded with fuel and ensure it is capable of withstanding the environmental extremes in an operating reactor under both normal and accident scenarios. None of the various joining approaches developed by industry, national laboratories, or academia up to this point have survived the irradiation and flowing water tests that mimic in-service reactor conditions. In addition, they are difficult and costly to manufacture.

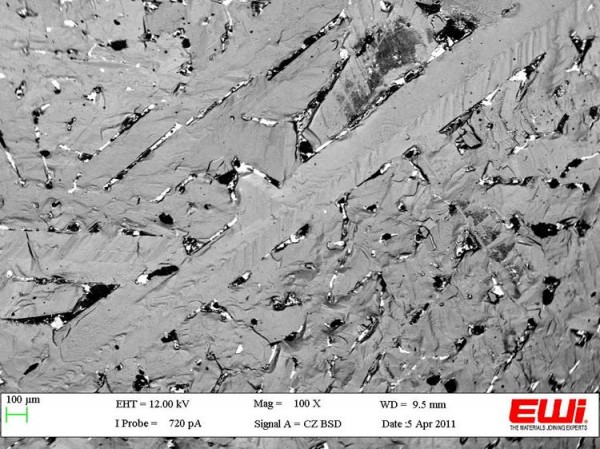

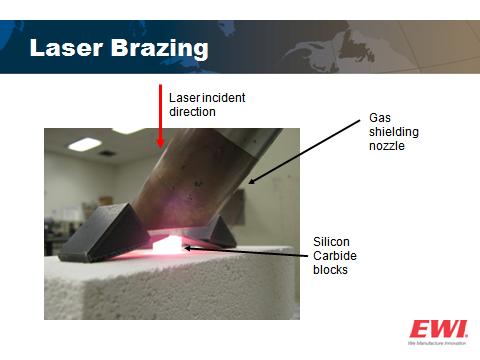

EWI developed a novel, patent-pending brazing approach to the fuel rod joining problem. After preliminary tests involving short duration irradiation in the Ohio State University research reactor and post-joining high-temperature cycling to 1200°C showed promising results, the EWI samples were entered into the MIT research reactor for six months of more aggressive testing.

Edward Lahoda, consulting engineer at Westinghouse Electric Company who has been leading efforts to develop a full-scale silicon carbide fuel cladding technology, said of the successful EWI testing, “This is an exciting development our team is watching closely as SiC-SiC joining is a key technology that is required to deploy silicon carbide cladding.”

Henry Cialone, President and CEO of EWI, said “We are very pleased at how well our new joining technology performed in the six-month MIT reactor test. This technology could be the missing piece in the silicon carbide cladding puzzle. It is repeatable and economically feasible for nuclear manufacturers, and could enable industry to make revolutionary safety improvements.”

For details, contact Ed Herderick, EWI Applications Engineer, at 614.484.7600 or [email protected].