Laser Processes

Wondering how to adopt – and adapt – laser welding technology or systems for your organization?

EWI can identify and customize laser processes for the unique manufacturing application you have in mind, sticking with you from concept to implementation.

We’re experts at combining tooling design, automation and laser systems to develop specialized instrumentation devices for industries like aerospace, defense, off-highway manufacturing and others that require uncommon solutions like these:

- Custom optics

- Coating removal (such as laser paint stripping)

- Specialized cladding

- Multiple approaches to laser additive manufacturing

- Laser welding of unique materials

EWI’s laser labs continually contribute to the evolution of laser materials processing and related high-powered optical technologies. Our in-house teams work together closely to provide the breadth of technical insight our partners need to consider which high-precision laser systems are right for their application – from pipelines to nuclear storage containers to pacemakers.

In addition to working out technological details, we’re dedicated to rigorous beam quality analyses and material performance testing, especially when working with unproven materials or novel methods. We stay in close communication with our clients through every step, such as estimating manufacturing costs and performing QA.

Why Choose EWI for Laser Processes?

We’ve been deep in laser system research, development, and implementation for 25 years and have been privileged to help tackle high-impact projects like these:

- Developing the first motion system for high-speed laser welding of delicate fuel cell components

- Completing defect-free 12-foot welds on aerospace alloy, using our patented high-powered optics

- Patenting a powerful laser scanner for paint stripping, and assembling a team of international collaborators to develop a mobile laser paint-stripping robot

We help organizations shorten development cycles when adopting laser processes. A major reason we’re able to do this effectively is our wealth of in-house resources –metallography, metallurgy, and mechanical testing technology and experts. Our people are just as important as our broad suite of laser types, speeds (really fast), and power levels (50 watts to 20,000 watts).

Identify.

Develop.

Implement.

WE MANUFACTURE INNOVATION.

When you engage with us to solve your most difficult challenges, you get the support of not only the experienced laser team but also every EWI expert with applicable capabilities, from mechanical modeling to optics design.

Are laser processes right for your application?

Laser technology could be the capability your organization needs to optimize, advance, and innovate. Contact the EWI laser team today to learn more.

Technical Expertise

The majority of our laser-related work involves these technologies and processes:

- Laser welding – autogenous and filler material

- Laser additive manufacturing

- Directed energy deposition (DED) – powder and wire

- Laser powder bed fusion

- Laser coating removal, including paint stripping

- Laser surface modification

- Laser cladding

- Laser heat treating

- Weld joint and fixture design

- Advanced laser optics design

Lab Resources & Equipment

Laser Systems:

- 20 kW, IPG Ytterbium fiber laser

- 10 kW, Laserline diode laser

- 6 kW, Trumpf Disk Laser

- 4 kW, nLight Corona

- 3 kW, Lumentum Corelight laser

- 2 kW, IPG Ytterbium fiber laser, single mode

- 20 W, Laserline fiber delivered diode laser

- 150 W, Miyachi Unitek, pulsed Nd-YAG laser

- 100 W, Lumentum, diode laser

- 50 W, IPG Picosecond laser

- 50 W, IPG Q-switch laser

Supporting Equipment:

- Kuka, Motoman, Panasonic, and Fanuc robots

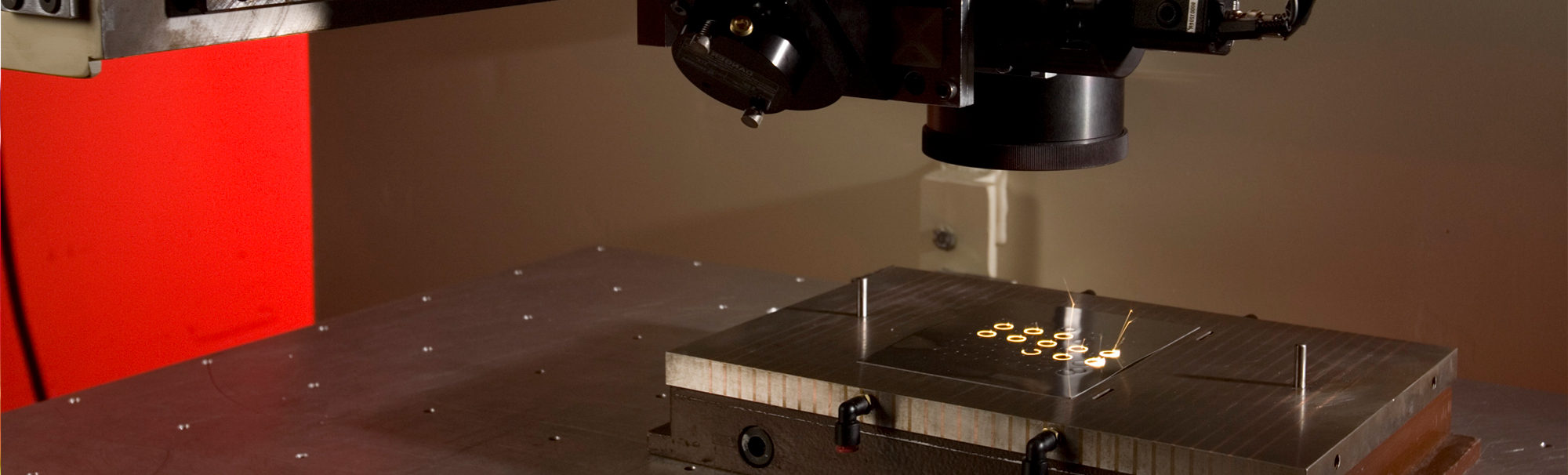

- Multi-axis CNC motion systems (Aerotech)

- High-speed CNC systems (EWI custom design with Aerotech linear motors)

- Large gantry-mounted robotic system

- Galvanometer scanners (Scanlab and Cambridge)