The hydrogen economy is forecasted to grow significantly. The infrastructure required to support its emergence means more materials will contact high pressure hydrogen as it is created, stored, transported, and used as a fuel. Seals, gaskets, and non-metallic pipelines are prime examples of polymers that hydrogen will readily encounter along its life cycle. Hydrogen is the smallest molecule, so it has fast transport properties. It can quickly diffuse into polymer materials up to their saturation level and cause swelling. Then, when the pressure is released (e.g., hydrogen is consumed or transferred), it causes supersaturation in the polymer. This leads to bubble nucleation and growth, causing irreversible damage to the polymer in the forms of micro-cracking, decrease in durometer, and embrittlement.

Manufacturers of hydrogen pumps, valves, pipelines, and storage vessels need to consider their polymer material selection carefully to avoid the use failures described above. Through pressurized hydrogen testing and polymer characterization, EWI has shown that some o-ring materials are susceptible to deleterious property changes.

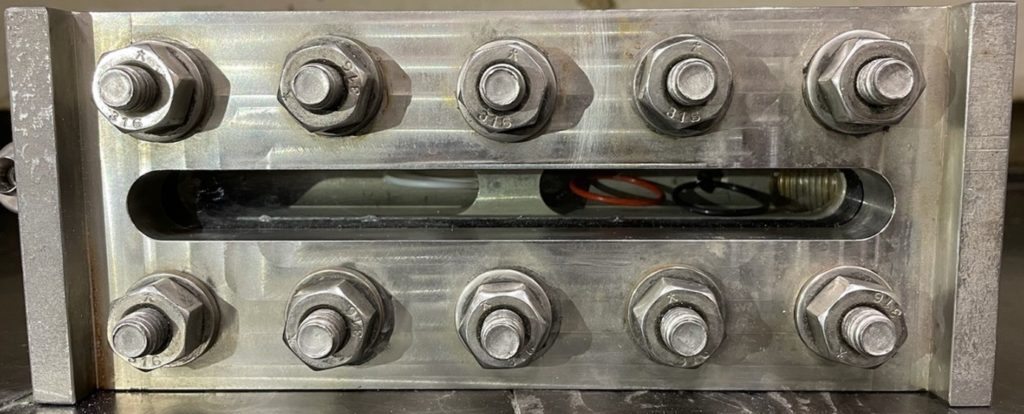

As part of a larger hydrogen testing laboratory, EWI has constructed a high-pressure hydrogen testing system. Recently, this system was used to soak elastomeric o-rings in hydrogen at 21°C and 2400 psi for up to 72 hours. The o-rings were visible while at pressure through the vessel window, see Figure 1.

The o-rings were characterized before and after hydrogen exposure for axial thickness, hardness, weight, tensile strength, and ultimate elongation. Our initial data showed:

- axial thickness increased up to 34% (substantial swelling)

- durometer decreased up to 8%

- weight was unchanged

- tensile strength decreased up to 35%

- ultimate elongation decreased up to 55%

The primary takeaway from this research is that these material property changes can cause leaks in industrial systems where o-rings are used to seal pressurize hydrogen, which is not only a revenue loss, but also a safety concern. To find out more about the effects of hydrogen on materials contact Jeff Ellis for polymers ([email protected]) and Josh James for metals ([email protected]).