With the passing of the infrastructure bill, the U.S. joins the world at large in making concrete investments in a hydrogen energy future. Transitioning to hydrogen (H2) as a utility-scale fuel source comes with many fundamental materials challenges. There are overarching research needs that relate prolonged service under H2 and degradation of mechanical properties, such as fatigue strength and fracture toughness in metals and polymers alike. To meet these needs, EWI is constructing a dedicated H2 testing lab that will serve the emerging fuels and energy production industry.

Like any potential fuel resource, H2 has a life cycle that includes production, transmission, distribution and end use. Examples of material challenges can be found at each stage along the way from proper materials selection for electrolyzer production to qualification of new materials for the expected service environments through conversion of legacy distribution infrastructure and the effects of H2 on aging materials and components.

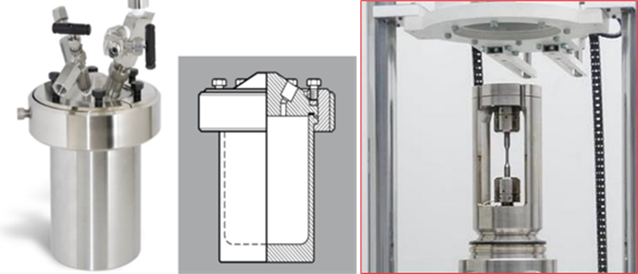

The EWI H2 environment testing lab will address these challenges and help inform operational decisions. We are building out 400 sq ft of lab space designed for safe operation based on preventing accumulation of minimum flammability limit of H2 gas. It will be outfitted with a dozen pressure vessels and three load frames for fracture mechanics testing in active hydrogen environments.

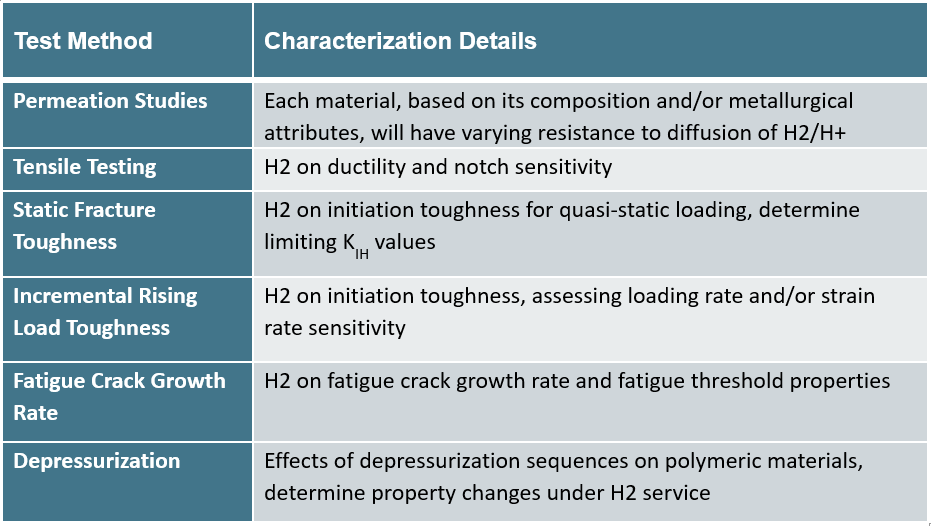

A selection of the types of tests we will be able to perform is as follows:

Construction of lab space is expected to be finished in the next few months. Any questions about the lab or the types of testing we will have the capability to perform, contact Josh James ([email protected], 614.484.7600).