PART II: THE ADOPTION OF CARBON EQUIVALENT

[This is the second of a four-part series titled The Great Minds of Carbon Equivalent.]

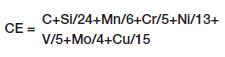

In 1958, eighteen years after Dearden and O’Neill’s initial proposal on carbon equivalent (CE), the concept was accepted by British Standard BS2642. The standard was then amended to include the following modified version of their equation:

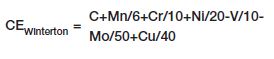

In 1961, Winterton reviewed twelve CE equations and presented his own:

It is interesting to note that Winterton considered V and Mo to be softening elements instead of hardening elements, which was unique in the evolutionary history of CE equations. In the same year, Kihara, Suzuki and Tamura[3] published their version …

Read the full PDF version of this article.

See also the previous part of this series: Part I