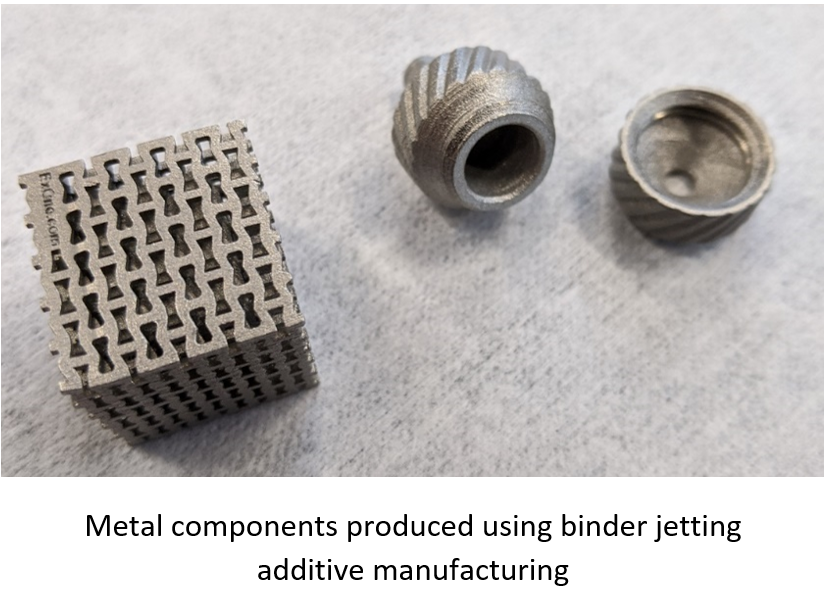

Binder jetting offers unique material options compared to high-energy deposition alternatives. Coupled with low running costs, binder jetting can provide an effective method to produce finished parts at nearly production-ready speeds. This additive manufacturing (AM) method is being considered for applications in high-volume industries such as automotive where it is cost-competitive to casting.

Binder jetting utilizes a liquid binding agent applied to layers of powdered material to quicky build complex geometries and parts. In contrast to high-energy powder bed fusion (PBF) systems, material consolidation in binder jetting does not occur in the printer itself. Separating heat treatment from printing enables more uniform heat application, reduces part distortion and warping, and frees up printer time to make more parts. Once the initial print is complete, the entire container is cured which makes the parts strong enough to be gently removed from the powder. These “green” parts do not possess final part strength and are still fragile.

The final processing step generally includes heat treatment in a vacuum furnace to burn off the rest of the binder, followed by either a sintering or infiltration process. A large industrial vacuum furnace can process significantly more parts and reduces the bottlenecks common in high-energy PBF. Often, manufacturing facilities already have these furnaces in place for other heat treatment processes. If not, the cost of purchasing a vacuum furnace is usually well worth the overall increase in throughput.

A unique feature of binder jetting systems is the broad application of different materials. High-energy output is not applied to the parts, so volatile material can be used. The process is also well-suited to materials that do not typically melt such as ceramics and composites.

Because binder jetting can accommodate a variety of materials, can print parts quickly, and can be executed in large build spaces without specific vacuum or heating requirements, this AM method offers a number of advantages – especially where higher production level throughput is needed.

With broad expertise in additive technologies, EWI can provide direction on how best to proceed to maximize your new investments.

Other questions about EWI’s AM capabilities and services? Click on the button below: