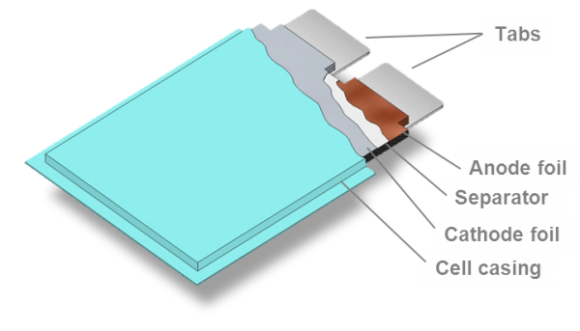

A standard electric vehicle (EV) automotive battery can be decomposed into cell level, module level, and pack level. A cell mainly includes the anodes and cathodes, a module includes multiple cells, and a pack includes multiple modules.

The three most common metal-to-metal joints in a lithium-ion battery pack are foil-to-tab, tab-to-tab, and tab-to-bus. All three joints pose joining challenges, but of the three, welding multiple layers of foil to a tab is the most challenging. The joint is often made up of dissimilar metals, and the metal thicknesses are mismatched. The tab is relatively thick (e.g., 0.2 mm) while the multiple foils are extremely thin (e.g., 0.025 mm). The image below shows a schematic of a large format lithium-ion pouch style cell.

The foil-to-tab weld is needed to gather all the anode and cathode foils inside the cell and join them to tabs which exit the cell casing allowing the cell’s energy to be transferred to an external source. There are two foil-to-tab welds in each cell, and hundreds of cells in a typical large format lithium-ion battery pack. Because of the series and parallel connections, one failure in a foil-to-tab joint will compromise the output of the entire pack. Therefore, a robust joining process is required to meet the joint requirements, such as satisfactory joint strength, low electrical resistance joint, and minimum intermetallic layers in joining dissimilar materials.

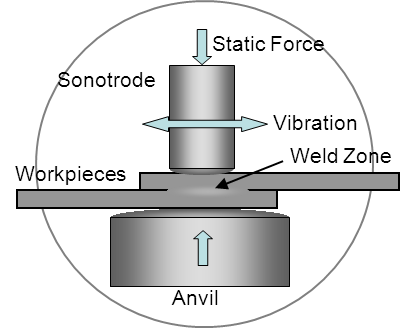

Ultrasonic metal welding (UMW) was evaluated for this particular application. A schematic of the process is shown below. Ultrasonic metal welding is capable of welding similar and dissimilar combinations of battery-related materials such as copper, aluminum, and nickel. Ultrasonic vibrations, typically 20 to 40 thousand Hz, are used to rub two parts together under pressure. The scrubbing action breaks off oxide and contamination on the surface and breaks down surface asperities creating two smooth, clean metal surfaces. Once these contact under moderate heat and pressure, a weld is formed.

The process has several advantages. Since it is a solid-state process, it can be adapted to dissimilar materials combinations and avoids most concerns about formation of intermetallic compounds. It is ideally suited to welding the highly conductive materials used in batteries including plated copper and aluminum. It does not require high power, and weld cycles are very short, fractions of a second. It also joins multiple layers of thin materials in one operation and provides a high strength joint with low resistance.

Other joining processes including soldering, magnetic pulse welding (MPW), resistance spot welding (RSW) and laser beam welding (LBW) were also considered, but they lacked certain attributes that make UMW a more desirable joining process for multi-layer foil to tab application.

- Soldering can be used for joining pouch cell tabs. It is especially desirable for joining dissimilar materials, but the use of flux can increase the chance of corrosion which can directly affect the strength of the joint.

- MPW can provide high strength joints, but the process can create large distortion and the induced current might damage the internal components of the cell. Note that the application of MPW for battery components is under research, therefore, this technology is not ready yet to be used by the battery manufacturer.

- RSW relies on the resistance of a material to generate heat for joining. However, the aluminum and copper foils typically used in the battery industry have extremely low resistance. In addition, aluminum alloys form a tough surface oxide layer which inhibits RSW and is further compounded by the fact that the oxide layer is present on both sides of each foil layer.

- LBW is very sensitive to gaps between material layers in the weld joint. As a general rule, the gap should be less than 10% of the material thickness. Joining a 12 µm foil would require a 1.2 µm, or less, gap which is very difficult to achieve and requires excessive fixturing. An additional issue with LBW is sensitivity in the use of reflective material.

UMW does not rely on bulk resistance and inherently scrubs away oxide layers as part of the process. Because UMW is self-clamping, gaps are not an issue. In addition, the UMW process is not sensitive to reflective material.

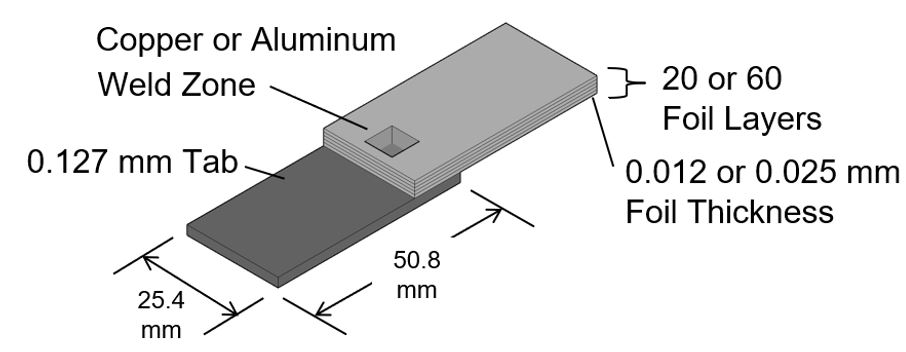

A typical large format lithium-ion cell uses copper foil as the anode current collector and aluminum as the cathode current collector; therefore, both copper and aluminum were evaluated with the UMW process. The experimental joints, as shown in the image above, were limited to similar material stacks only, meaning aluminum foils were joined to aluminum tabs and copper foils to copper tabs. The tab thicknesses were held constant at 0.127 mm. Two foil thicknesses, 0.012 and 0.025 mm, and two foil stack heights, 20 and 60 layers, were evaluated to prove feasibility and to study the effects on joint properties as the foil thickness and number of foil layers varies.

Analysis of the above cross sections provided a closer look at foil compression, foil damage, and the final state of the weld joint. The samples with thinner and fewer layers of foil show an increase in foil movement directly adjacent to the weld zone. In contrast, the samples with thicker and more foil layers showed a consolidation of the foils adjacent to the weld zone often resulting in a larger bond region. The consolidation and increase in bond region occurred because the thicker foil stacks bottomed out on the weld tool causing compression in the area adjacent to the weld zone.

Conclusions:

Joining multiple layers of thin foils to a tab in a single ultrasonic metal weld operation is feasible. The welds are achievable without fracturing the delicate foil layers. Bonding occurs at the foil to tab interface as well as at each foil-to-foil interface which results in a strong, highly conductive electro-mechanical joint. This process which is considered a low energy consumption process can be used for joining dissimilar materials in fractions of a second.

Infrared (IR) videography shows that all joints, except the copper sample made from 60 layers of 0.025 mm foil, stayed under 60 ºC during the weld cycle indicating the process will not harm nearby heat sensitive components. Below is IR videography of a 60-layer foil stack being welded to a tab. The segment of the video showing the weld cycle is slowed down dramatically to illustrate the heat generation in a large foil stack.

If you would like further information about EWI’s services and work related to innovations for battery welding, please click on the button below:

To speak to a technical expert immediately, please contact Amin Moghaddas at 614.484.7600 or by email at [email protected].