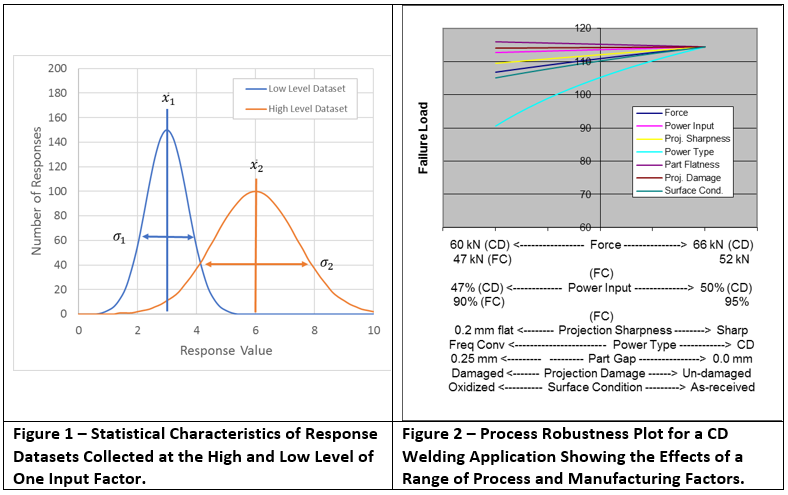

Design of Experiments (DOE) methods have been used as a tool for industrial research for many decades. These methods allow empirical correlation between defined input data factors and any number of responses from the process of interest. For example, in resistance spot welding input parameters might be current, weld time, and force. Responses would then be weld diameter, nugget penetration, joint shear strength, etc. The experimental designs themselves are essentially input factor combination arrays. These arrays are used to map process response using relatively simple linear equations. Designs are selected to provide differing resolution of the resulting correlations between input and response factors. Designs commonly include two levels of each factor. These are configured so there are equal numbers of high and low levels for each factor included. Analysis of these designs is based on averaging the response from two data subsets (high and low for each factor) and comparing the results statistically. An example is shown in Figure 1 below. Correlation is established by comparing means and standard deviations for these two data sub-sets. This allows identification of any correlation as well as an average response magnitude. EWI has used these methods in hundreds of programs to assist in interpreting process capability. EWI’s methodology includes first establishment of the most efficient experimental design, data collection, normalization of the resulting datasets, regression curve fitting, and development of process robustness plots. An example process robustness plot for capacitive discharge welding of an automotive suspension component is provided in Figure 2.

The plot shows changes in weld strength as a function of power supply type as well as process and manufacturing factors. The response is optimized to the values on the right side of the plot. Of note, the application represented is sensitive to only changes in the power supply type (here from a CD to a frequency converter system) All other factors have very limited influence on joint strengths. The plot indicates a process that would be quite robust in a manufacturing environment.

At EWI, the techniques have been used to investigate applications incorporating the breadth of process technologies available at EWI, as well as a comparable number of material systems. The techniques remain a powerful research and development tool, particularly for complex applications with a wide range of input factors and physical experimentation might be costly.

Jerry Gould, EWI Technology Fellow for Resistance and Solid-state Welding, can be reached at [email protected].