EWI is investigating the use of an advanced SEM technique for evaluating ferrite percentage and intermetallic content (i.e. sigma phase) in duplex stainless steels such as 2205, 2507, 19D, etc… The technique involves use of Electron Back Scattered Diffraction (EBSD), also known by the trade name Orientation Imaging (OIM). The current plan is to contact the original sponsors of an EWI Joint Industry Project on ferrite content/count and sigma phase detection (Project 47288CPQ) to determine if they would be interested in expanding upon the previous program to include this emerging microstructural analysis tool.

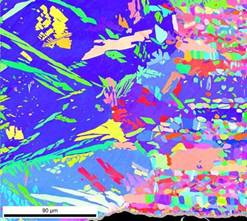

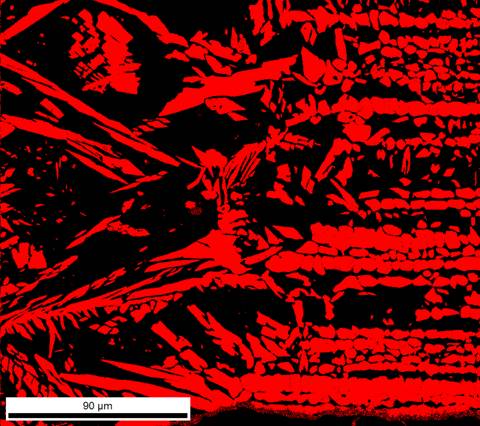

The attached images display the output of an EBSD scan of a SAF2507 weld specimen. The first multicolored image displays the standard output from an EBSD scan. The individual colors within the scan correspond to distinct crystallographic directions; therefore, each unique block of color represents an individual grain of metal. The exact same crystallographic data that is used to generate the first image can be used by the EBSD software to generate other useful images. The second image consists of a filter of the first image for crystallographic structure; the black ferrite matrix (BCC) is starkly contrasted by the red austenite phase (FCC). This stark contrast will allow for the use of image analysis for precise determination of ferrite percentage. In theory, intermetallic phases with distinct crystallographic phases may also be readily identified using this technique. Imagine the second image for an improperly welded 2507 DSS having 1-5% sigma phase (complex tetragonal crystal structure); the d/g boundaries would be decorated with bright green sigma nodules that would be incredibly easy to visually identify and quantify.