EWI has recently developed internal capabilities to perform the VDA 238-100 standard testing for tight radius v-bending of sheet materials using digital image correlation (DIC).

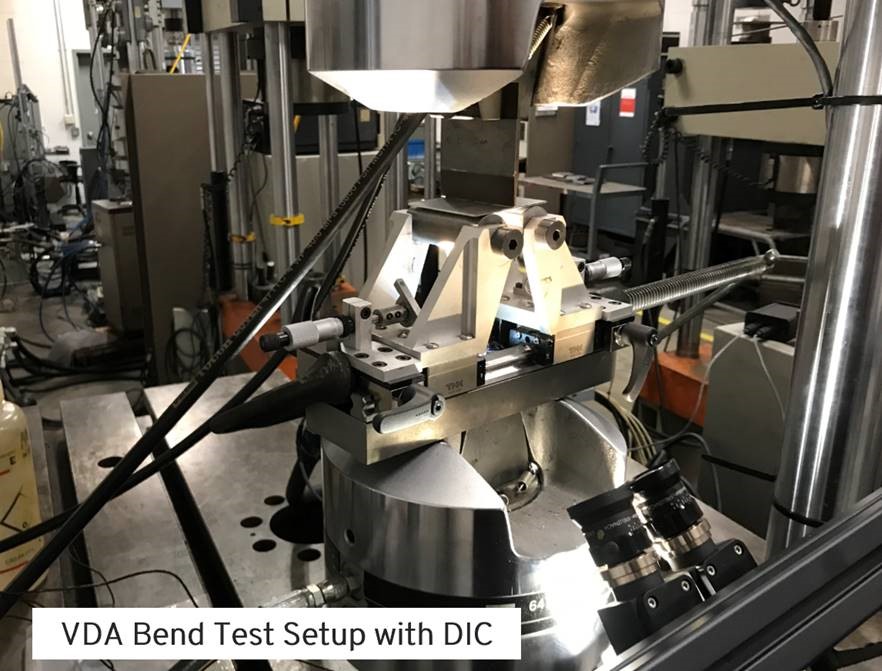

Bendability has become a crucial property as the automotive industry sees increased use of advanced high strength steels (AHSS) and aluminum alloys in sheet metal structural parts for light-weighting and crashworthiness. The bending strains and fracture models are needed to predict the material’s failure accurately during a crash. Conventional VDA bend test tools are limited to obtain the bending strains and angles without a real-time strain measurement tool. Therefore, EWI’s VDA bend test tool uses DIC to measure the bending strains and angle during the tight bend as seen in the figure here.

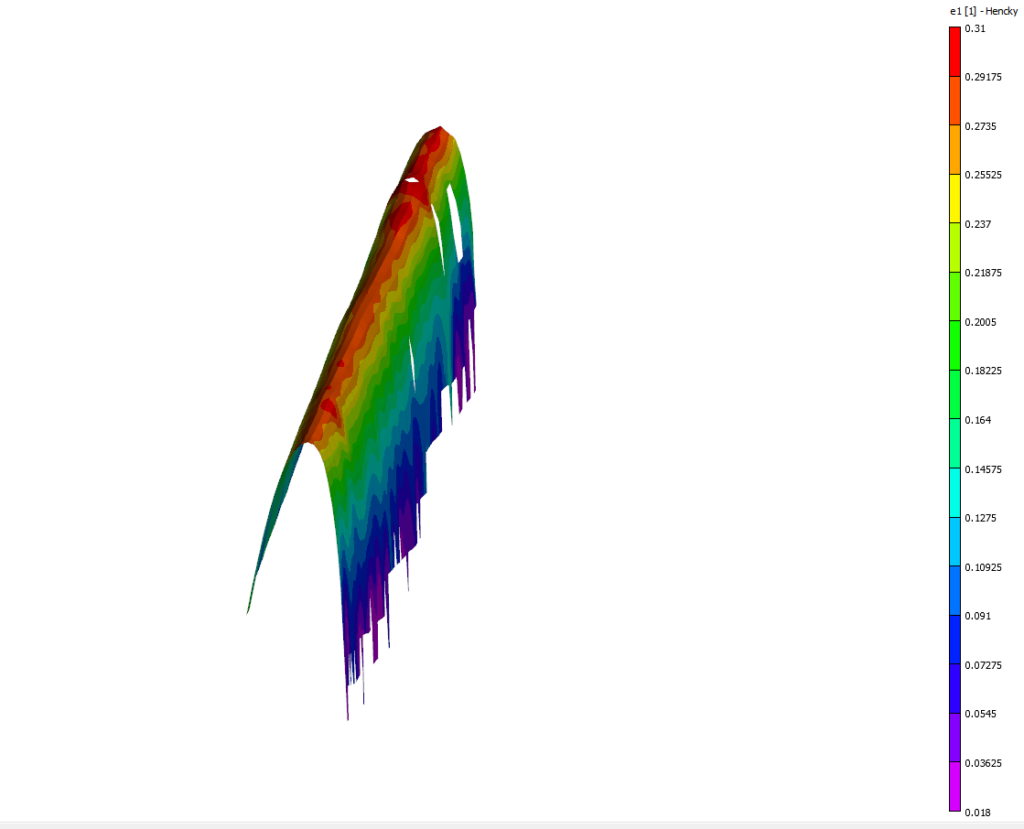

The bending strains and angle captured with DIC during the test can then be implemented into the fracture model for simulation engineers to more accurately predict the material’s crash performance.

The deliverables for EWI’s VDA Bend test include load-displacement data, bending angle measurements using DIC and analytical methods, major and minor strains during the test.

If you are interested in learning more about EWI’s VDA Bend test capabilities, please contact Hyunok Kim ([email protected]) or Laura Zoller ([email protected]).