DECISION MAKING TO DRIVE MANUFACTURING PROFITABILITY

In today’s media-rich environment where information is abundant and cheap, it’s easy to get overwhelmed. Between the blogs we find on social media and the resources we get in our inbox, we’re often left more confused or distracted than we are informed and empowered.

So, how do we improve decision making in a world of too much information? Answering that question is the primary goal of our latest article, Decision Making to Drive Manufacturing Profitability. But unlike most of the content you’ve consumed today, this article simplifies your decision-making process by outlining a simple framework of three core principles.

These principles can be applied in multiple ways to organize information and make decisions that will ultimately help maximize profitability. While every operation is unique, we share three case studies to demonstrate different ways to put the framework into action.

To learn more, download our guide for free by completing the form on this page.

OUR CAPABILITIES

EWI is the only independent engineering consultancy with comprehensive labs and advanced manufacturing technology resources dedicated specifically to production process development and improvement.

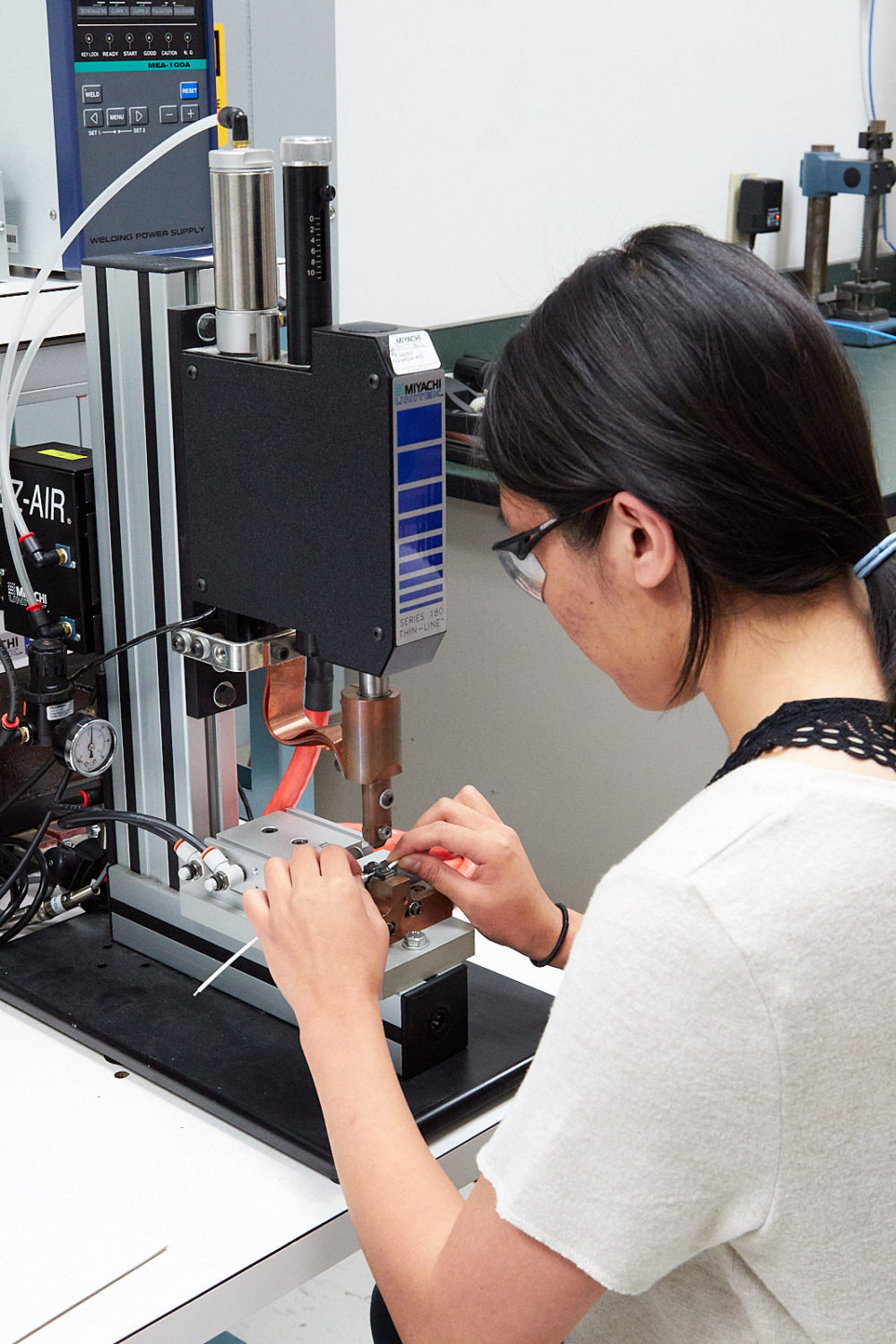

Welding & Joining

Over time, we’ve stayed true to our welding roots while redefining the limits of industrial joining processes, developing game-changing techniques for both fusion and solid-state processes. Welding and joining remain core services at EWI, but we have a much more advanced suite of capabilities than we did in 1984. Learn More

Additive Manufacturing

EWI supports broad adoption and optimization of advanced metal 3D printing and large-scale additive manufacturing technologies throughout all industrial sectors. Learn More

Metal Forming

The EWI Forming Center helps organizations evaluate new forming technology so they can fully harness it for their operations. Learn More

Advanced Automation

Automated processes and robotics have long been used to handle the physically difficult, repetitive, and even dangerous tasks previously performed by humans. They have also helped address workforce shortages and lack of skilled labor in several industries. Learn More

NDE & Inspection

EWI’s Nondestructive Evaluation (NDE) group designs and develops inspection technology for a broad range of applications. We use manual and automated inspections, custom equipment designs, and mathematical modeling to tackle the most challenging inspection problems. Learn More

Structural Integrity & Design

Ensuring structural integrity is critically important for pipeline operators, automakers, oil and gas companies, ship builders, and manufacturers of industrial machinery. Learn More

Testing & Lab Services

EWI’s dedicated laboratory testing services team manages a comprehensive inventory of testing equipment and standardized procedures for rapid characterization of the chemistry, properties, and performance of metals, plastics, and composites. Learn More

Questions?

When reevaluating your own operation, it can be useful to work with an unbiased evaluator to identify your opportunities for improvement.

To speak to an EWI specialist about your project or need, contact 614.484.7600 or [email protected]

Complete this form to download the paper:

Contact Our Experts

Give us a call today or fill out a contact form to get in touch with one of our technical advisers. We can work with you to identify, develop, and implement the right solution for your manufacturing process.

Contact Us