Walter (welding engineer): Hi, Michael. I know you are doing modeling work for welding but I am not sure how this can help people like me. Could you explain it to me?

Michael (modeling engineer): Yes, Walter. As we all know, various welding methods have been widely adopted to join materials together. There are all kinds of welding-related issues. Let me find an example to show how the modeling can help.

Walter: How about welding-induced distortion? I was doing an arc-welding yesterday. It was a simple butt joint. I clamped two plates on the anvil as I learned in my training. After the welded plates cooled down, I took them from the anvil and found they are no longer flat.

Michael: As you know, welding involves intense heat input in a localized area. The heated material will expand its volume. However, this volume expansion is resisted by the neighboring materials. The interaction between the heated material and the neighboring material results in stress. A similar scenario occurs when the welded parts cool down, except the neighboring material is now resisting volume shrinkage. It is the stress that causes the distortion.

Walter: Yes, I have heard something like this before but I don’t know if I really understand it. I can see distortions, but I cannot see stress.

Michael: Ok, that is something I can help you. Temperature and stress are the basic physical quantities we are interested. In modeling, we try to predict them.

Walter: How do you do that?

Michael: The change of temperature and stress in welding process is controlled by some physical laws which we call governing equations. To predict temperature and stress, we solve the equations. To give you an analogy, think of this: You throw a piece of stone in the air. The stone flies along a trajectory, going up first then falling down. This trajectory can be calculated based on the fundamental physics.

Walter: Are you talking about Newton’s law? I learned this in school.

Michael: Yes, it is called Newton’s law. For temperature and stress, we have similar laws.

Walter: Then, you will have to solve them. It is not easy to get the solution, is it? I remember it took me a while to calculate how far the stone can fly.

Michael: You are right that it is not easy to solve them through hand calculation. Nowadays, we use computer and engineer software to solve the problem.

Walter: Could you tell me more? I am curious to know.

Michael: Basically, you have to let the software know what problem you want to investigate. This includes a lot of details such as the geometry and material of the weldment, the welding conditions, and the issues you are interested in.

Walter: So, it sounds like I have to be familiar with the software. This will require certain training and practice. Right?

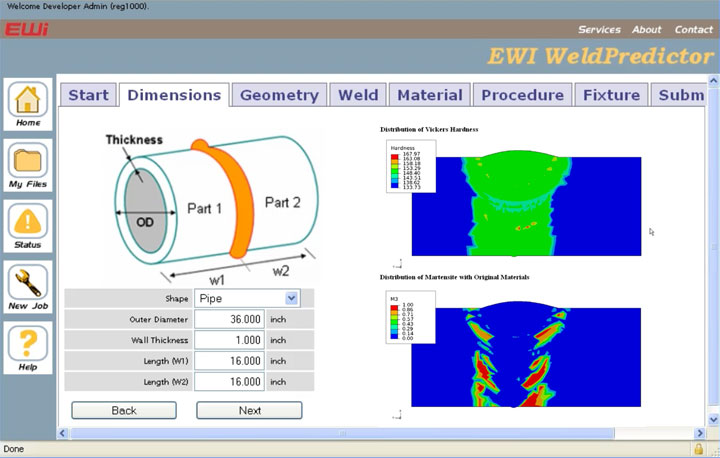

Michael: Yes, but I have some good news for you. In order to help welding engineers, EWI has developed a welding analysis tool called EWI WeldPredictor. The tool is essentially the customization of the analysis of common arc welding processes, such as GMAW, GTAW, etc. It can analyze the welding of a wide range of plate and pipe joints. Welding engineers can input the welding parameters they are interested through a Graphic User Interface and launch analysis to predict the residual stress, distortion, and microstructure. After the analysis is finished, a report will be generated to summarize the results. The analysis tool is installed on EWI’s members-only website. It is free for EWI members to use.

Walter: Wow. This seems to be very attractive. Since our company is a member, I’d like to give a try. Do you offer any training on it?

Michael: The use of this analysis tool is very straightforward. Simply follow the web pages and the instructions. You will find no training is needed. I will set up an account for you and send you the login information. At this point, I would suggest you to login to WeldPredictor and try to analyze a few welding processes. Then, based on the analysis, we can have further discussions on the distortion issues you are interested in.

Walter: Great. Thank you very much. I definitely will try it and get back to you.

~ For more information, contact Junde Xu, EWI Senior Engineer at [email protected] or 614.688.5176.~