This is a Technical Brief written by Dr. George Ritter, Principal Engineer in our Materials group. George can be contacted at 614.688.5199 or [email protected]. You can view George’s bio here. If you are interested in this article, you may also be interested in another article on lightweighting.

Composites as Structural Materials

Composites provide directed, purposeful stress management using strategic placement of reinforcing fibers, often combined with core materials to provide stiffness. Fiberglass reinforced composites have been used in marine and other extreme environments for decades. Carbon fiber reinforced composites offer the ultimate in strength-to-weight ratio and are now universal in aerospace and marine applications. Modern materials have tensile modulus equal to that for aluminum, half that for titanium, and one-third that for steels. Structural composites offer many advantages in weight savings, corrosion resistance, and design versatility.

Why Bond Composites to Metals?

Joining composites to metals often invokes mechanical fasteners, such as rivets or bolts. This requires hole drilling, which is expensive. The composite and metal thicknesses must be increased overall to accommodate the stress concentrations at the hole and fastener point loads, sacrificing weight advantage. The holes and fasteners invite corrosion problems along with the potential contact of the carbon reinforcements with the metal, inviting galvanic corrosion.

Bonded structures overcome many of these issues. First, the entire bonded contact surface participates in load management. The adhesive and primer combination isolates one surface from another which sharply reduces issues from galvanic interaction. Because the joining system provides more efficient load management, the thickness and weight of both materials can be reduced. And there are no holes to drill, align, or seal. The strength of a bonded composite system is typically limited by the ability of the composite itself.

Engineered Bonded Systems

How Do I Design a Bonded System?

EWI offers comprehensive contract engineering services to develop bonded system solutions. We have worked with fiberglass-based, carbon-based, and cored-wall reinforced systems, including bonded applications to carbon steel, stainless steel, aluminum, and titanium. The EWI Adhesives team has experience with primers and corrosion control materials to develop the best combination of corrosion protection, bonding strength, and adhesive for the materials being combined. Drawing upon internal resources, EWI forms an engineering team to provide design, FEA, analysis, adhesives and primer selection, testing, and structural verification along with the program management to integrate our work with yours. This enables us to provide Engineered Bonded System solutions.

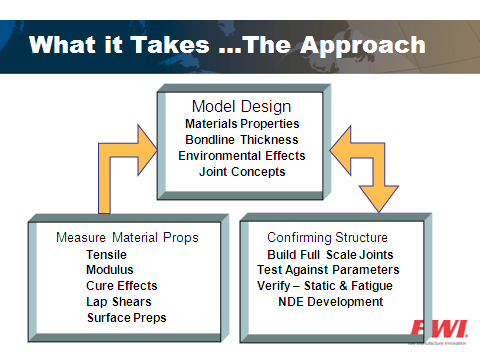

Teamed with your structural engineers, EWI develops a modeled joint design based on the demonstrated effectiveness of preferred shear joint and socket joint configurations. This requires a 3D CAD drawing which is often supplied by the client design team. A custom experimental plan is developed with the client. Critical material properties are collected or measured at EWI and entered into the resulting FEA design.

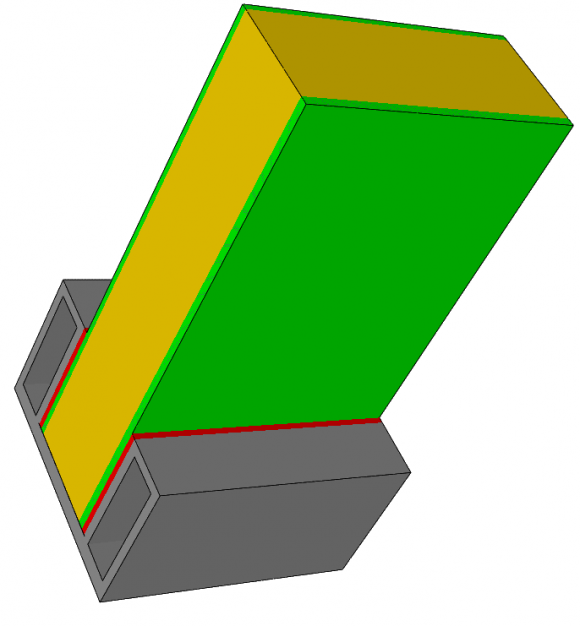

Cored Wall in Socket or Clevis Shear Joint Configuration

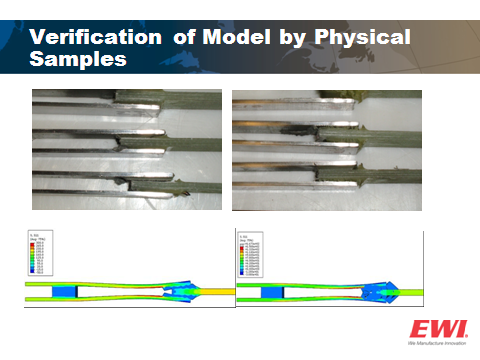

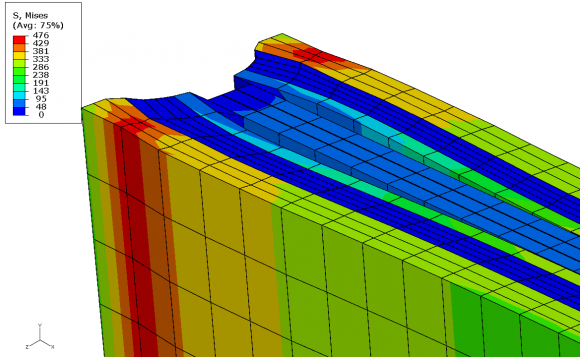

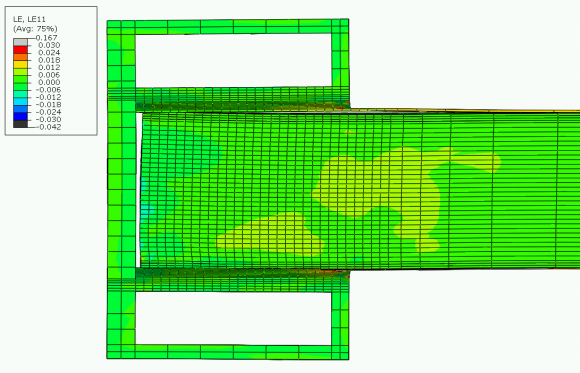

Joint design and analysis begins based on nominal material and load values. The final design requires actual values for the proper combination of selected adhesive, primer, and surface preparation. Test specimens are built to measure effects of variables such as temperature, humidity exposure, corrosive environment exposure, bondline thickness or variability, and cure conditions. The model is first calibrated against control test specimens. Then the manufacturing and operating extreme conditions are introduced and their effects are predicted. Finally, calculated factors of safety (FOS) are developed to quantify structural redundancy in the design.

Modeled System at Ambient and Elevated Temperature, Verified Against Actual Specimens

Modeled Lap Shear and Cored Composite Structures Showing the Bond is Stronger than the Composite Itself – A Successful Design

Once the model is calibrated, performance predictions can be generated. After developing a test plan with the client, a full-scale demonstration article is produced for verification tests of the bonded system. EWI can produce the test articles or work with the client to produce them at their facility. EWI develops a construction crawler sequence document to begin the manufacturing transition. We can also provide training and onsite assistance.

Other Client Needs

Bonded structure offers an attractive package of load management and design efficiency. It also offers the opportunity to use the most efficient and intelligent combination of materials. How does the client know the system is functionally trustworthy?

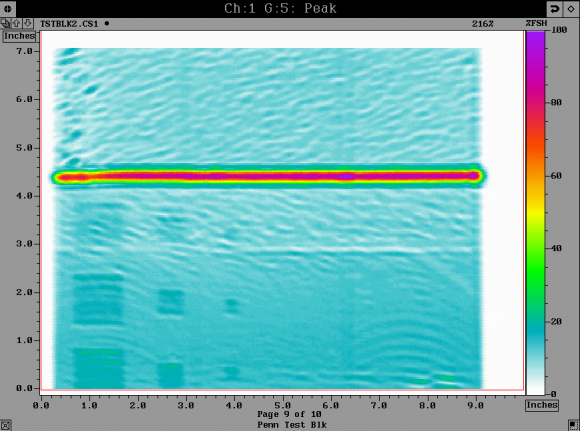

NDE Scan of Composite-Metal Interface Showing Implanted Defects

The design and modeling methodology is aimed at providing a design with the necessary factor of safety under all design load conditions. Normally, that range is FOS = 1.2 to 2, depending on the requirements. EWI also offers development of NDE techniques that address the complications of using multiple materials with an adhesive interlayer.

You can download a copy of this information here.

About EWI

EWI is the largest North American organization dedicated to the advancement of materials joining technologies for manufacturing industry. With some 220 industrial members from all manufacturing sectors, EWI also provides joining technology development for the Department of Defense and Department of Energy. Our nearly 100 technical staff, many with advanced degrees, represent disciplines in welding engineering, materials science, mechanical engineering, modeling, NDE, and testing services. Onsite joining technologies include all welding methods, adhesives bonding, brazing, and soldering for metals, plastics, composites, and ceramics.