There are two types of heating “modes” used to describe the resulting melting of the metal during laser welding. These are called “conduction mode” and “keyhole mode” heating. These modes of heating are created by different power densities and produce different results. Power density is defined as the power of the laser beam divided by the area the focused laser spot.

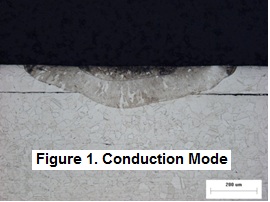

In conduction mode heating, the power density is great enough to cause the metal to melt. Weld penetration is achieved by the heat of the laser conducting down into the metal from the surface. An example would be pulsed laser welding in the millisecond pulse length range. The depth of the weld penetration is controlled in part by the length of the pulse. The longer the pulse the more time heat has to “conduct” into the part. In conduction mode heating the welds are typically wider than they are deep.

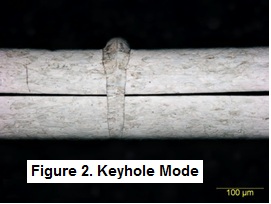

Keyhole mode heating achieves its weld penetration in a different way. During keyhole mode welding the power density is great enough that the metal goes beyond just melting. It vaporizes. The vaporizing metal creates expanding gas that pushes outward. This creates a keyhole or tunnel from the surface down to the depths of the weld. As the laser beam is moved across the surface, the keyhole follows and creates a typically deep and narrow weld. As long as the laser power is great enough and the travel speed is not excessive, this keyhole will remain open.

Below are metallographic cross sections of both types of welds. Figure 1 shows a pulsed Nd:YAG laser conduction mode weld. Figure 2 shows a continuous wave keyhole mode weld. There are advantages and disadvantages to each. The desired weld joint, the part fit-up, the weld performance, and the required weld speed are all considered when deciding which heating method to use.

For more information about EWI’s laser welding capabilities, contact [email protected] or 614.688.5152.