Designers at EWI often need to take precise measurements of extremely small parts. Measurement of small parts using calipers has two problems:

- Errors associated with measurements using traditional calipers become significant on a small scale

- The pliable nature of small parts makes them susceptible to distortion when measured with calipers, which yields inaccurate results

A promising option is to measure small parts optically using high magnification camera images to derive size measurements. After evaluating several equipment options, EWI has added a measuring microscope to our lab.

The Dino-Lite microscope is capable of 20 to 250X magnification. Fitted to a stand, the microscope enables the stationary inspection of parts. The stand also integrates auxiliary spotlights, and fixed LED lighting to illuminate the samples. The camera lens incorporates a polarized filter, enabling measurements of highly reflective parts without interference from on the parts. All of these features work together to produce quality images.

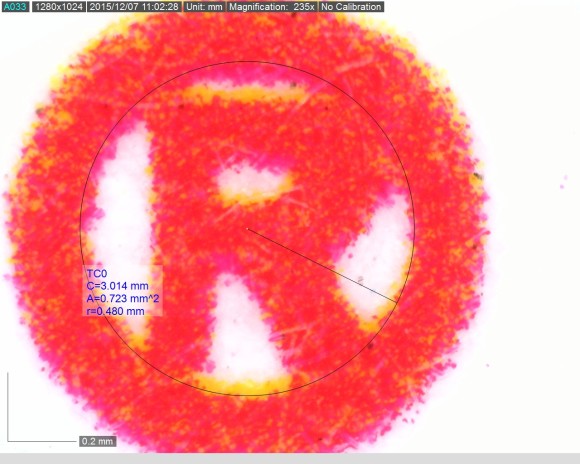

Images from the microscope camera are processed using DinoCapture software. The software enables images to be saved, and visible features to be measured. The software includes a variety of tools for measuring straight-line distances, diameters, radii, and angles. The following images show the “rights reserved” symbol on EWI’s logo magnified to 20, 40, and 235 times normal size. The third image shows DinoCapture’s diameter tool measuring the inside diameter of the symbol as smaller than a half millimeter.

Nearly all welding processes require work pieces to be fixtured correctly. In the case of small parts, discrepancies in fixture design can have a significant impact on weld quality. The small measurement capability of the Dino-Lite microscope will enable small parts to be accurately measured, so custom fixtures can be designed that hold parts effectively, improving weld quality.

For more information on fixture design at EWI, visit the Design, Controls, and Automation group.

For more info on working with small parts, visit EWI’s microjoining website here: https://ewi.org/technologies/ultrasonic-processes-main/#microjoining