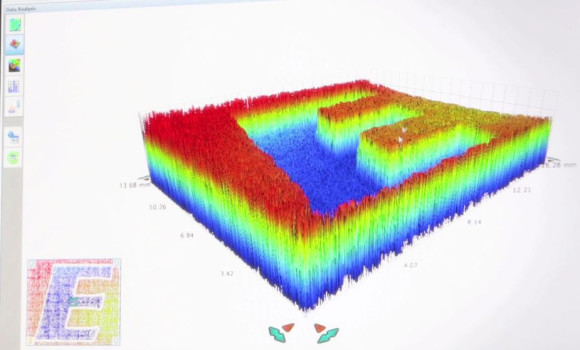

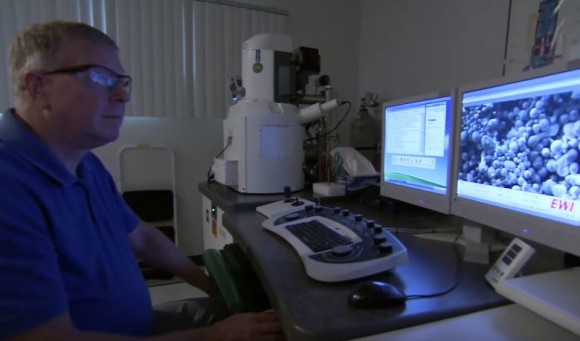

At EWI we have some serious testing capabilities, ranging from our 500,000 lbs-force servo-hydraulic machine to our high-precision non-contact optical surface metrology measurement equipment. While our extensive equipment list gives an indication of what we can do, EWI’s most important offering is realized when our technicians and e

At EWI we have some serious testing capabilities, ranging from our 500,000 lbs-force servo-hydraulic machine to our high-precision non-contact optical surface metrology measurement equipment. While our extensive equipment list gives an indication of what we can do, EWI’s most important offering is realized when our technicians and e

ngineers work together to provide comprehensive start-to-finish testing and analysis services. This integrated approach empowers our customers through reliable test results, in-depth and specialized analysis, and valuable recommendations based on our years of diverse combined experience.

ngineers work together to provide comprehensive start-to-finish testing and analysis services. This integrated approach empowers our customers through reliable test results, in-depth and specialized analysis, and valuable recommendations based on our years of diverse combined experience.

EWI provides a comprehensive array of standardized testing services as well as more specialized services including failure analysis, design optimization, API RP 2Z material qualification, and resonant fatigue testing, to name a few. Our materials experts use everything from our SEM to our thermogravimetric analysis system to provide customers with extensive metallography and characterization services. Our skilled welders and welding operators conduct full-service weld consumable qualification testing including environmental conditioning, diffusible hydrogen testing, heat treatment, and more. In addition to destructive testing options, our nondestructive evaluation group offers high-level expertise in cutting-edge inspection technologies such as phased array ultrasonic testing, eddy current inspection, and computed tomography.

EWI’s multidisciplinary laboratory testing services team has this and much more to offer. We offer unique and broad-ranging capabilities available for your company’s benefit. Think of our team as an extension of your own – one that provides data plus interpretation to enhance your processes and products.

For more information or to discuss your more specialized testing needs, please contact EWI.