Testing & Lab Services

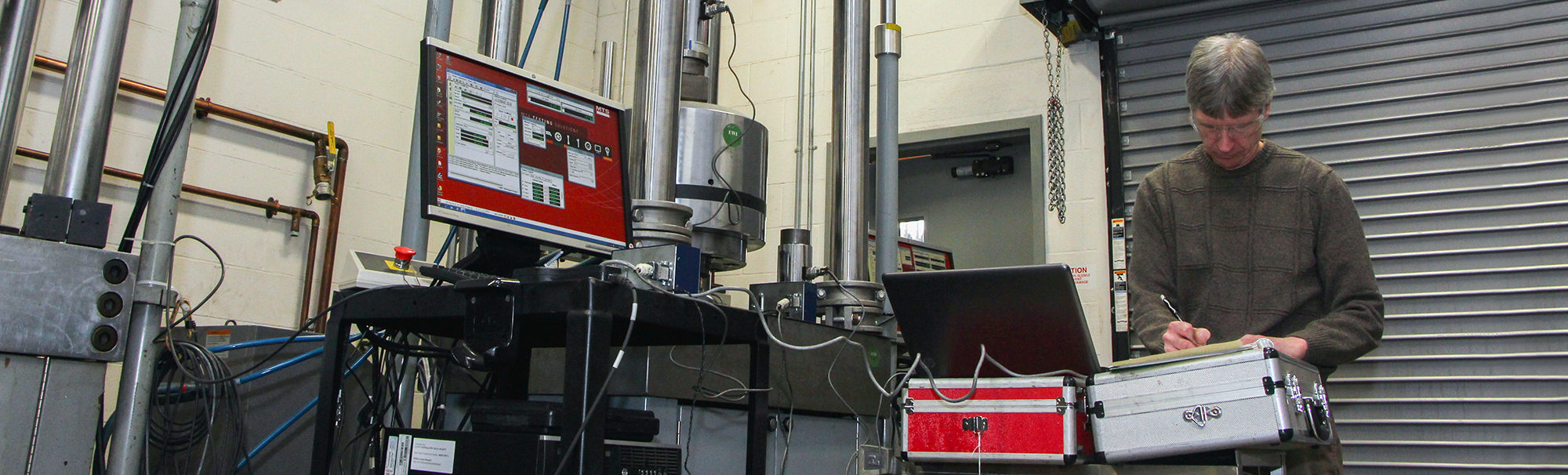

With precision equipment and a world-class engineering team, EWI is uniquely qualified to offer a full range of testing.

Beyond traditional failure assessment, our experts seek out the root causes to help our customers manufacture the highest quality products.

EWI’s dedicated laboratory testing services team manages a comprehensive inventory of testing equipment and standardized procedures for rapid characterization of the chemistry, properties, and performance of metals, plastics, and composites.

This extensive testing capability is often coupled with our material and process-specific engineering expertise, enabling us to deliver services including but not limited to:

- Failure Analysis

- Production Troubleshooting

- Design Optimization

- Product Conformance

- Procedure/Operator Qualification

- Materials Evaluation

To view the EWI Lab Services Scope of Accreditation to ISO/IEC 17025:2017, click here.

Services Offered

Mechanical Testing

- Tensile

- Bend

- Impact (Charpy, Drop-Weight, Nil-Ductility)

- Fatigue Crack Growth Rate

- CTOD (SENB, CT, SET, SENT)

- KIC (SENB, CT)

- R-Curve (SENB, CT, SET, SENT)

- Fatigue (Force or Strain Control)

- Residual Stress

Nondestructive Evaluation

- Ultrasonic (Contact and Immersion)

- Phased Array

- Eddy Current

- Radiography

- Computed Tomography (CT)

- Visual Inspection

- Magnetic Particle Inspection

- Liquid Penetrant Inspection

- Metrology

- Surface Characterization

Specialized Services

- Resonant Fatigue

- Pressure/Burst Testing

- Varestraint Testing

- Gleeble

- Failure Analysis

Metallography / Material Characterization

- Digital Photography (Micro and Macro)

- Linear Image Analysis

- Chemical Analysis (AES)

- Oxygen/Nitrogen Elemental Analysis

- SEM/EDS/EBSD

- Thermogravimetric Analysis (TGA)

- Differential Scanning Calorimetry (DSC)

- Hardness (Vickers, Knoop)

- Hardness (Rockwell)

- 2D Hardness Mapping (Micro-Vickers)

- G48 Corrosion Testing

- Grain Size Average

- Delta Ferrite Content (Magnegage)

- Percent Ferrite

- Porosity Measurement

- Inclusion Content

- Microstructure Analysis

- Metallographic Examination

- Particle Size/Morphology Characterization

Weld Consumable Qualification

- Welding (GMAW, SMAW, GTAW, SAW)

- Diffusible Hydrogen

- Moisture Content

- Fillet Weld

- Nick Break

- Y-Groove

- Controlled Thermal Severity (CTS)

- Environmental Conditioning

- Heat Treatment

Lab Testing Equipment

Universal Screw Machines

- 10,000 lbs-force

- 60,000 lbs-force

Servo-Hydraulic Machines

- 5,000 lbs-force (Qty 2)

- 35,000 lbs-force

- 50,000 lbs-force (axial and torque)

- 100,000 lbs-force (Qty 3)

- 200,000 lbs-force

- 220,000 lbs-force

- 500,000 lbs-force compression only

Bend Testing

- Semi-guided (wrap-around) bend tester

- Various 3-point guided bend test fixtures

Impact Testing

- Charpy V-Notch Machine (300 ft-lb)

Drop Towers

- 5000 ft-lbs

- 2500 ft-lbs (instrumented)

Metrology

- Scienscope XT-2000 measuring system

- Alicona IF Robot measuring system

- Bruker Nano Inc. NPFLEX 3D metrology system

- Novacam Technologies MicroCam-4D profilometer

- Keyence Laser Displacement Sensor

- Hexagon Metrology Global Performance Silver Edition CMM

Specimen Preparation Equipment

- Abrasive cut-off saw (Qty 2) – 12-14” diameter

- Mounting press (Qty 5)

- Automatic Polisher/Grinders (Qty 5)

- Table top polishers (Qty 6)

Microscopes

- Optical Microscopes with integrated digital cameras (up to 1000X)

- Olympus DSX510 Digital Microscope (up to 1800X)

- PAX-it software

Specimen Analysis

- LECO GDS500A CCD-Based Glow Discharge AES

- Leco RC612 Multi Carbon Determinator

- Leco ON836-MC Oxygen/Nitrogen Analyzer

- Agilent 7890B Gas Chromatograph

- Zeiss EVO 60 SEM with EDS

- Hitachi S-3700 SEM with EBSD and EDX

- Nicolet Magna-IR 560 Spectrometer

- Beckman Coulter Multi-wavelength Particle Size Analyzer and Tornado Module

Hardness

- Clark CR-1eA Rockwell Hardness Tester

- Leco R-260 Rockwell Hardness Tester

- Buehler MV 1680 Macro-Vickers (5kg to 30 kg)

- Leco M-400 Micro-Vickers (10g to 1000g)

- Leco LM 247 Automatic Micro-Vickers (10g to 1000g)

Welding Consumable Qualification

- Multiple Arc Welding power supplies (up to 1000 amps)

- ArcAgent 3000 weld data acquisition systems

- 6-axis welding robots

- Side-beams

- Welding carriages

X-Ray Equipment

- Varian NDI-320-23 Stationary Anode X-Ray Tube

- AFP Mini-Med 90 Automatic Film Processor

For a complete list of EWI’s testing services, click the button below:

Services include:

- Mechanical Testing

- Metallography

- Weld Consumable Qualification

- NDE and Inspection