As a technology innovation organization dedicated to advancing the state of manufacturing, EWI frequently develops new diagnostic tools to improve production processes and efficiencies. Companies can work with EWI to take advantage of these cutting-edge applications for testing, inspection, and increased productivity.

Over the last few months, EWI has released three diagnostic tool sheets to help customers explore the various ways EWI can help identify tough manufacturing challenges. In the coming months we will continue to add to this knowledge base:

- Fourier-Transform Infrared Spectroscopy with Attenuated Total Reflectance Attachment (FTIR-ATR) to identify surface contamination that can cause failure in ultrasonically welded plastic parts

- Digital Image Correlation for Full-field Displacement and Strain Measurements to gauge deformation with high accuracy and larger surface coverage

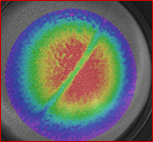

- X-ray Computed Tomography (CT) for internal, nondestructive product inspection and validation

Are you looking for better ways to evaluate your materials, inspect your finished components, or trouble shoot a production issue? EWI can help. For more information about our tools and services, contact [email protected] or 614.484.7600.