More and more, robotic welding is becoming a viable option for use in heavy fabrication. The sophistication and capacity of modern robot systems is suitable for large structures which require multi-pass welds. Processes used for heavy fabrication such as preheating, gas metal arc welding (GMAW), flux cored arc welding (FCAW), tandem gas metal arc welding (T-GMAW), submerged arc welding (SAW) or flame cutting can all be deployed robotically. An example of a mult-pass weld that was made with a robot is shown below.

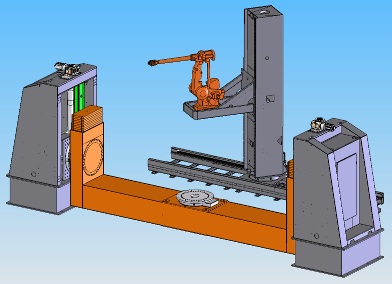

One of the challenges with automating heavy fabrications is the high mix low volume nature or this type of work. To maximize the production time of the robot, an off-line programming tool should be utilized. Off-line programming, or OLP, has matured to a point where it can be used without an operator touching up program points. An example of a virtual system used in an OLP software is shown below. To succeed with OLP in high mix low volume applications OLP should be used in conjunction with robotic options that search for the weld start location and track the joint while welding. Some systems are even capable of adaptively filling a weld joint that varies in volume along the length. EWI has significant experience in creating multi-bead multi-layer adaptive welding solutions for third party equipment platforms.

When considering moving to automation from a manual or semi-automatic process it is important to consider many factors. The quality of the parts that will be feeding the robotic welding system are very important and will directly influence the level of productivity possible from the system. Consistent dimensions, part fit-up, and surface condition are important factors to control on the parts that feed the robot system. When parts are more consistent, higher production rates can be achieved. Deciding whether you want to pre-tack parts, or use hard tooling is another consideration. Using a tack fixture and presenting a tacked part in a holding fixture to the robot can be more cost effective and allow more access for the robot to perform welding.

Probably one of the most important things to consider is the selection of the personnel that will be responsible for the robotic welding in your facility. The welding is by far the most difficult portion of applying automation to heavy fabrication, the robot and system portion are easy to deal with in comparison. I would much rather have someone that knows about welding learn how to teach and operate a robot than try to teach a CNC programmer about welding. The best welding robot programmers that I know are experienced welders or have a welding background.

If you would like to discuss the possibilities of using automation in your facility, please feel free to contact me at 614.688.5000 or [email protected].

Thanks for your interest in EWI. If you liked this post, you may also like this article on high-speed welding of aluminum.