Cross-industry lightweighting initiatives have significantly increased the use of aluminum and magnesium in fabrication; however, welding of these alloys presents a unique set of challenges. Arc welding processes offer significant advantages ranging from relatively low equipment costs and high productivity levels, with a range of process variations available to address productivity and quality requirements. A new article, Arc Welding of Aluminum and Magnesium by EWI Applications Engineer Nick Kapustka, provides an overview of these processes, discusses common challenges associated with welding these materials, and provides useful recommendations.

To download the article, click here.

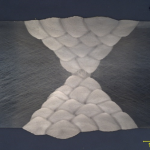

1.5-in thick magnesium