Developing a New Model to Predict AM Part Performance

In additive manufacturing (AM), post-processing steps are just as crucial to the success of the final product as the build itself. That’s why both the build process and the post process need to be taken into account in models that predict AM part performance. A new performance prediction tool for AM-built parts has been developed […]

Read More

New Non-contact Thermography Inspection Available at EWI

While conventional flash thermography is ideal for polymer materials, it can be challenging when used with metals due to reflectivity of the component. With pulsed eddy-current-assisted thermography (PECT), ferrous and non-ferrous steels, as well as titanium, can be inspected without surface reflection interference. Internal research on flattened, painted, and steel pipe is ongoing at EWI […]

Read More

Aeromat 2021

Aeromat 2021 May 24-26, 2021 A Virtual Event Four EWI associates will be presenting this year at Aeromat 2021: Putting Materials and Process Research to Work: Transitioning from the R&D Lab to Application — Ron Aman, Principal Engineer, Tuesday 3/25 at 10:00 am. Relation of Surfact Texture and Surface Finishing with Design of Additive Manufacturing […]

Read More

AWS Professional Program 2020

AWS Professional Program 2020A Virtual Event November 18-20, 2020All talks will be presented at Pacific Standard Time Several EWI associates will present their research this year at the AWS Professional Program: WEDNESDAY, NOVEMBER 18TH — ARC WELDING APPLICATIONS PROGRAM: Pulsed-arc Welding of Battery Tabs for Vehicle Electrification, Tim Frech, Senior Engineer (1:40 pm) Buried Arc […]

Read More

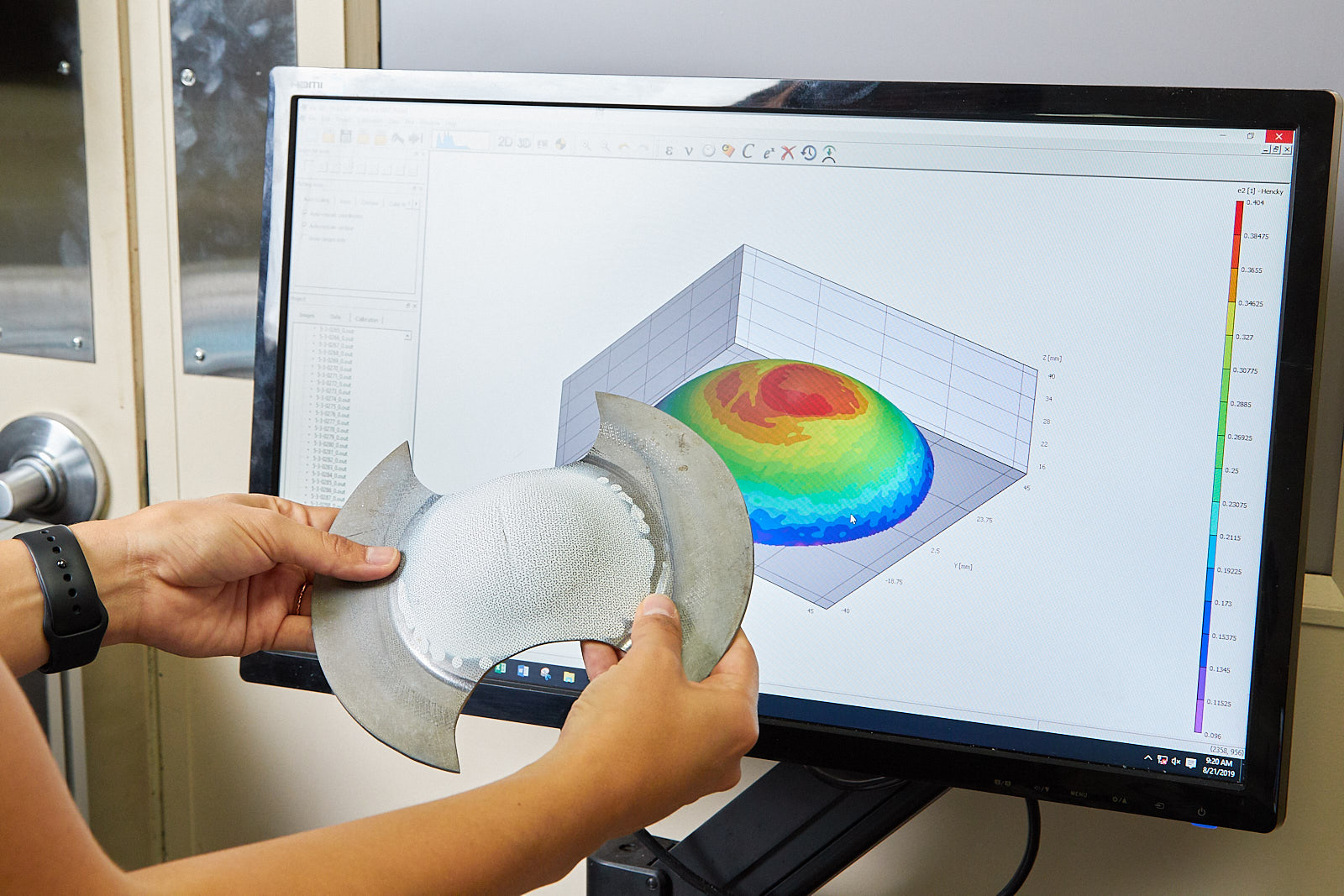

Evaluate the Formability of Your Material Today

EWI offers a comprehensive suite of material formability tests for sheet material including steel, aluminum, titanium, and nickel alloys. Our experienced engineers evaluate the results of these tests to provide recommendations on lubricants, coatings, and materials for your specific application. Learn more about our material testing capabilities. EWI’s Formability Testing Capabilities The EWI forming labs […]

Read More

Application of Micro-friction Welding for Dissimilar Metal Joints

Friction welding, a solid-state process that uses high-speed spindles to weld materials, is notably effective for joining dissimilar materials. EWI has recently developed a new micro-friction welder for small-scale, dissimilar metals joining. The system has been demonstrated on both aluminum-to-titanium and aluminum-to-stainless joints. Application of Micro-friction Welding for Dissimilar Metals, a paper by EWI’s Jerry […]

Read More

EWI and MTI to Cooperate in Technology Development of Low Force Friction Welding

Technology innovator EWI is pleased to introduce Manufacturing Technology, Inc, as its newest Strategic Technology Member. Together, EWI and MTI, a leading manufacturer of inertia, direct drive, and hybrid friction welders, will work in collaboration to advance the new hybrid joining technology known as low force friction welding. “Low force friction welding is a break-through […]

Read More

Forming

The EWI Forming Center helps organizations evaluate new forming technology so they can fully harness it for their operations. Our advantage is twofold: We have the materials expertise and technology to test, refine, and innovate new solutions. Advanced forming capabilities in the EWI Forming Center are supported by the following: These resources enable our engineers to […]

Read More

Additive Manufacturing Consortium

EWI established the AMC in 2010 to accelerate and advance the manufacturing readiness of metal additive manufacturing technology. Goals The AMC brings together a diverse group of additive manufacturing (AM) end users, suppliers, researchers, and stakeholders from across the nation to positively impact the AM landscape through organized and focused activities. The four aims of […]

Read More

EWI DuraStir

EWI DuraStir EWI has been on the leading edge of Friction Stir Welding (FSW) since its inception in the early 1990s. We have advanced FSW for hard metals with EWI DuraStir and EWI DuraStir for R&D. These proprietary tools are used to weld hard metals such as steels, titanium, and nickel-based alloys using FSW. EWI […]

Read More