Applying Low Force Friction Welding to Titanium

Low force friction welding, the robust joining process that combines friction welding and an external heat source, has been validated for metals including steels, aluminum alloys, copper, and more. Recent studies have demonstrated its great potential for titanium alloys as well. Application of Low Force Friction Welding to a Ti-6AL-4V Alloy, written by EWI Senior […]

Read More

EWI Titanium Weld Color Inspection Kit

EWI Titanium Weld Color Inspection Kit The Titanium Weld Color Inspection Kit from EWI provides fabricators of titanium with a high quality, comprehensive tool for performing weld color inspection as part of their weld quality assurance process. The kit is commonly deployed for visual inspection of titanium weldments across all industries, including defense, aerospace, chemical […]

Read More

Joining of Steel to Titanium with Interlayers — New Paper

As manufacturers turn to multi-material designs to meet the ever-growing demands on their products, many are faced with the challenge of how to join dissimilar materials. Using traditional joining techniques, metallurgical incompatibilities of certain material combinations have greatly limited the performance and viability of many dissimilar joints. In order to achieve maximum performance from a […]

Read More

Joining of Steel to Titanium with Interlayers

A new article byJerry Gould, Technology LeaderMichael Eff, Applications EngineerKate Namola, Engineering Intern EWI’s new layer-heating approach allows efficient and effective prediction of the evolution of temperature, stress, strain, and distortion in L-PBF components to help manufacturers optimize designs, process parameters, and build sequences to minimize distortion. To download the article, click here. Recent research […]

Read More

Joining of Composites to Titanium

We have had recent interest in looking at methods to join thermoplastics and thermoset composites to titanium from both the aerospace and medical communities. Generally, thermoset composites have higher temperature resistance than thermoplastic materials and must be bonded because they do not melt. Thermoplastic materials are easier to mold and will flow when heated. Therefore […]

Read More

New Improved EWI Titanium Weld Color Inspection Kit!

The EWI Titanium Weld Color Inspection Kit – now considered the standard for visual inspection of titanium welds across all industries – has been upgraded to include new high definition color inspection cards. The redesigned card set was created using a new photographic technique which renders a more realistic, “truer” color image than that of […]

Read More

Laser Processing of Titanium provides High Productivity Fabrication

Laser Processing of Titanium Brian Victor | Applications Engineer, Laser Processing Fuel efficiency is driving the use of titanium and other light-weight materials in new aerospace applications. Due to fluctuating titanium costs and stricter buy-to-fly requirements, alternatives to forged or billet-machined components are becoming more attractive. Alternatives such as laser welding and laser additive manufacturing […]

Read More

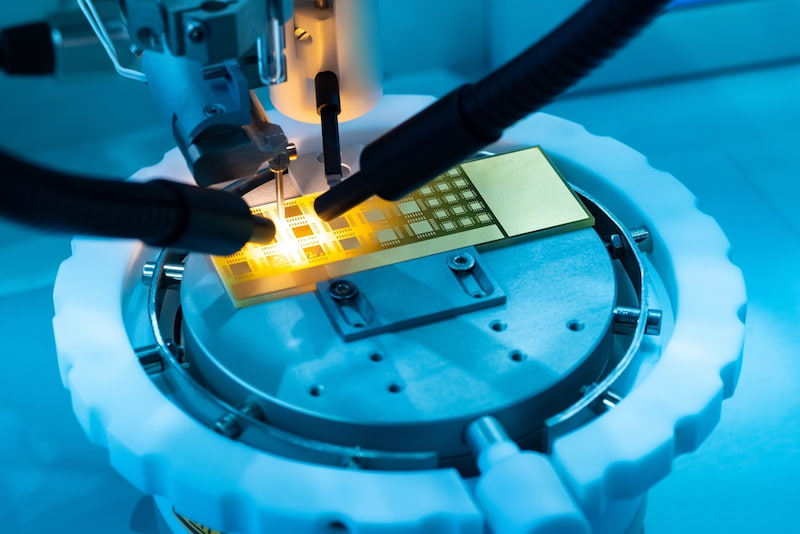

Consumer Electronics

Success in consumer electronics manufacturing requires tight design-to-market timelines, streamlined production processes, and minimized costs. Understanding the interdependencies of these elements can make or break a new product. EWI helps companies develop consumer electronics manufacturing solutions and efficiently adopt them. We apply our cross-industry experience and process expertise to address your unique challenges in complex […]

Read More

Medical Devices

In medical device manufacturing, shrinking development timelines and budgets are at odds with simultaneous requests for improved product performance and functionality. How can you get your products to market faster and more reliably? EWI’s expertise in manufacturing technology for medical products includes battery development, welding of dissimilar and unique materials, polymer processing, nondestructive testing, and […]

Read More

Resistance-based Sintering: A Breakthrough in Metal Consolidation Technology

Resistance-based sintering is a highly effective method for consolidating metal powders that combines the use of axial pressure with a flowing, high-intensity current without the need for atmospheric chambers. EWI began developing this technique a couple of years ago in an effort to replace spark plasma sintering. Our team made use of its considerable resistance […]

Read More