Consumer Electronics

Success in consumer electronics manufacturing requires tight design-to-market timelines, streamlined production processes, and minimized costs. Understanding the interdependencies of these elements can make or break a new product. EWI helps companies develop consumer electronics manufacturing solutions and efficiently adopt them. We apply our cross-industry experience and process expertise to address your unique challenges in complex […]

Read More

Medical Devices

In medical device manufacturing, shrinking development timelines and budgets are at odds with simultaneous requests for improved product performance and functionality. How can you get your products to market faster and more reliably? EWI’s expertise in manufacturing technology for medical products includes battery development, welding of dissimilar and unique materials, polymer processing, nondestructive testing, and […]

Read More

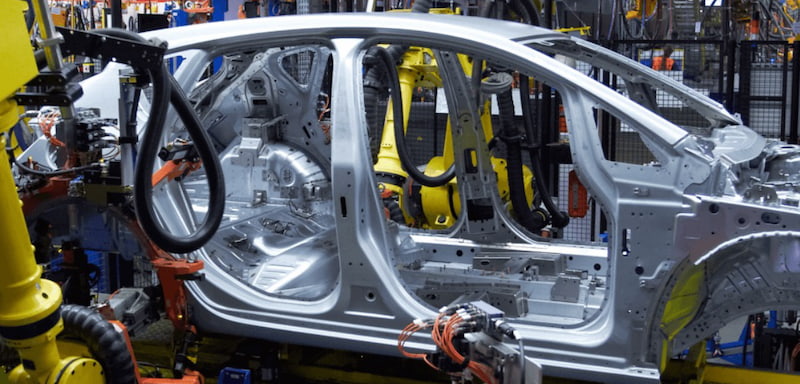

Automotive & Transportation

In the auto industry, doing more with less is imperative for success. Solve your most complex manufacturing challenges with advanced automotive engineering services from EWI. EWI develops and adapts production technologies and processes that enable vehicle manufacturers and suppliers to incorporate new materials, elevate product design, and increase manufacturing efficiency while meeting sustainability goals. What […]

Read More

In-process Inspection Paired with AI/Machine Learning Create Powerful Quality Assurance System

Are you seeking an automated solution to assess quality, reliability, and safety in your manufacturing operation? EWI recently worked with materialsIN to develop a real-time quality assurance system for ultrasonically welded, lithium-ion battery tabs. In a new paper, A Fully Automated Quality Assurance Solution for Battery Tab Welds Using Process Monitoring and AI, EWI engineers […]

Read More

Using FEA as an ICME Tool to Predict the Performance of Structures

Integrated computational materials engineering (ICME) uses analytical and numerical tools to create predictive models. Recently, EWI has published a series of papers examining analytical methods that work well in assessing thermal/mechanical responses in specific joining processes. Some highly complex joining applications, however, require advanced computational tools such as finite element analysis (FEA) to achieve desired […]

Read More

International Automotive Body Congress 2023

IABC 2023: 30 Years of Automotive Engineering Excellence September 27-28, 2023 Laurel Manor, Livonia, Michigan Two EWI associates will present at IABC 2023:

Read More

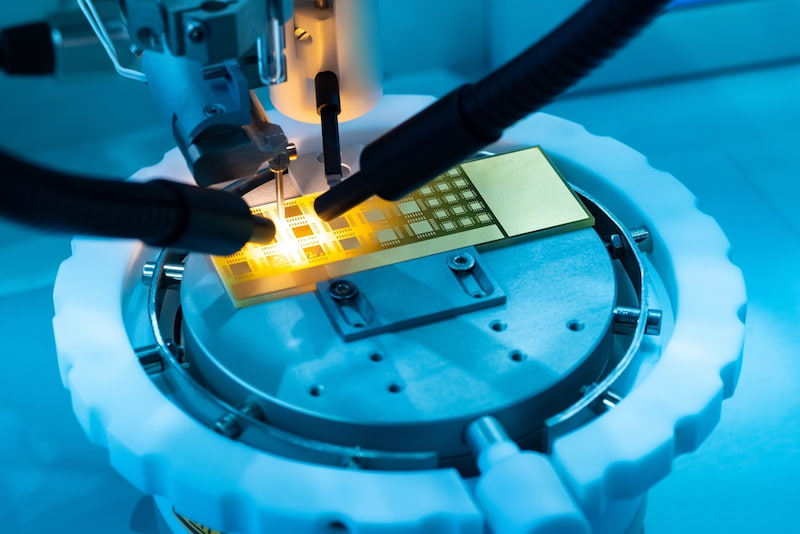

When Smaller is Better: EWI’S Microjoining Capabilities

Microjoining encompasses techniques including welding, brazing, soldering, and adhesive bonding. Typically, the technology involves materials with thicknesses less than 0.5 mm. Micro-welding techniques can be applied to join both similar and dissimilar materials combinations. Here are some key applications of microjoining today: For over 30 years, EWI has been developing and applying microjoining technologies to […]

Read More

Electric & Hybrid Vehicle Technology Expo 2023

Electric & Hybrid Vehicle Technology Expo Presented at The Battery Show/North America September 12-14, 2023 Suburban Collection Showplace, Novi, Michigan Please visit the EWI exhibit at the Electric & Hybrid Tech Expo, Booth #544. EWI associates Doug Myers, James Cruz, and Dale Robinson look forward to meeting with you there and discussing EWI innovations that […]

Read More

UIA51 Symposium

Ultrasonic Industry Associate Symposium (UIA51)Hybrid event April 24-26, 2023Grand Hotel Karel V, Utrecht, The Netherlands EWI Project Engineer Amin Moghaddas will present On The Effect of Laser Surface Preparation on the Quality of Ultrasonic Wire Bonding Process in Battery Pack Assembly at UIA51 on Wednesday, April 26th, at 10:00 am EDT. For information about viewing […]

Read More

No More Mess: Bonding Plastic to Metal without Adhesives

By James Cruz, EWI My first job out of college at Honda of America Manufacturing was a dream come true—the chance to play with robots and build cars! They handed me several crisp, white uniforms on day 1. Within that first week on the production line, however, I had soiled my pretty white pants with a huge, […]

Read More