Plastics and Metal Joining — How Small Can You Weld?

The newest generation of a product is typically lighter, smaller, and more powerful than its predecessor. For these products to be as successful as the previous iterations, they must be manufactured in an economical and reliable manner. In many cases, this requires going back to the drawing board to select materials, finalize a design, and […]

Read More

Application of Micro-friction Welding for Dissimilar Metal Joints

Friction welding, a solid-state process that uses high-speed spindles to weld materials, is notably effective for joining dissimilar materials. EWI has recently developed a new micro-friction welder for small-scale, dissimilar metals joining. The system has been demonstrated on both aluminum-to-titanium and aluminum-to-stainless joints. Application of Micro-friction Welding for Dissimilar Metals, a paper by EWI’s Jerry […]

Read More

Welding & Joining

EWI was founded to advance welding and joining technology. Welding held us together in our early years and was the foundation of our growth into the engineering innovators we are today. Over time, we’ve stayed true to our welding roots while redefining the limits of industrial joining processes, developing game-changing techniques for both fusion and […]

Read More

What is Ultrasonic Welding?

When the question “What is Ultrasonic Welding?” appeared on the Q&A website Quora, EWI Applications Engineer Miranda Marcus stepped up to reply. Her succinct essay, covering both metal welding style and plastics welding style, is a clear and straightforward introduction for the technically curious. To read Miranda’s brief article on quora.com, click here.

Read More

Just Published: Comparing Methods for Plastics Assembly

Congratulations to EWI associate Miranda Marcus on her recently published article in Assembly (magazine): “Comparing Methods for Plastics Assembly.” Reading this article is a great way to learn more about plastics assembly. Explore the options for welding plastic parts — such as ultrasonics, laser, hot plate, and radio frequency — as well as factors to […]

Read More

The Crazy Brilliance of Radio Frequency Welding

The Crazy Brilliance of Radio Frequency Welding When it comes to welding plastics, three contributing factors matter: heat, force, and duration. While there are multiple ways of controlling and applying each of these, the heating method defines the welding process: Welding Process Heating Method Vibration Surface Friction (linear) Spin Surface Friction (rotational) Hot Plate Conductive […]

Read More

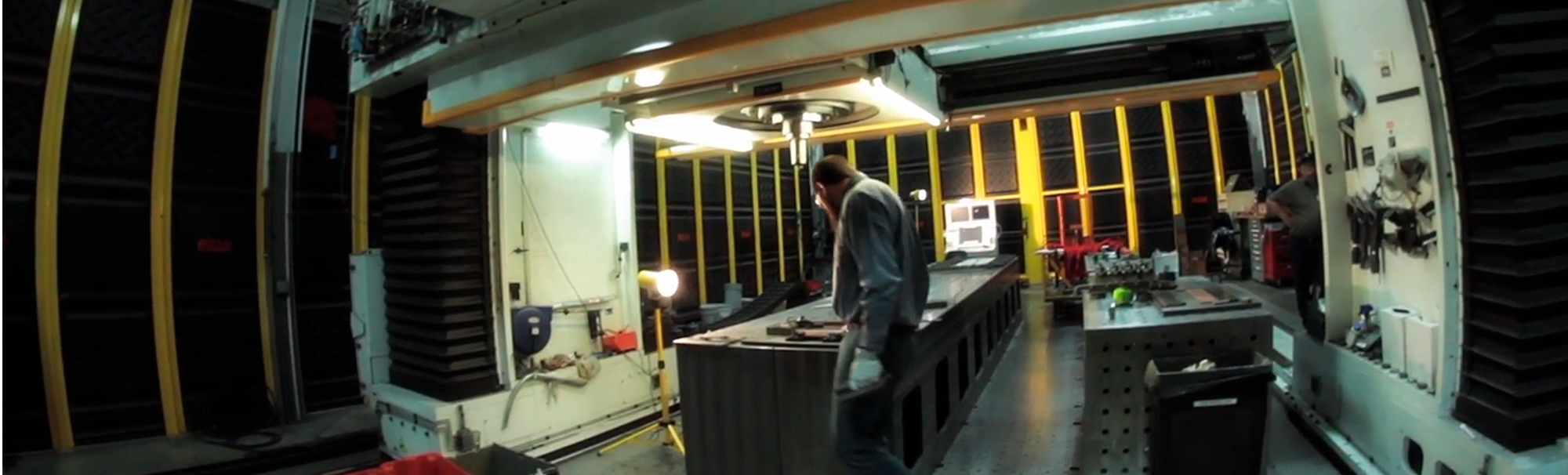

Manufacturing Innovation for the Common Man – Linear Friction Welding (Part 3 of 8)

Here’s a test to see if you’re a Common Man… If I asked you (95% of the people reading this blog) to describe what welding is, I’m guessing you would describe one of two things: Arcs and/or Sparks. When I started here at EWI as CFO, I pictured either a guy flipping down his welding […]

Read More

An Improved Plasticity-Based Distortion Analysis Method

Dr. Yu-Ping Yang, EWI Principal Engineer in Structural Integrity and Modeling, was recently published in the Journal of Materials Engineering and Performance Online First on November 11. The print copy will be following in coming months. To optimize welding sequence to control distortion, a new theory was developed to consider the effect of weld interactions on plastic strains. […]

Read More

Friction Stir Welding (FSW) Meet the Team – Zak Pramann

Today’s “Meet the FSW Team” features Zak Pramann. Zak has been at EWI for four years and comes to us fresh from the South Dakota School of Mines and Technology. Being a metallurgical engineer, Zak provides a unique perspective to the FSW team – helping to explain the mechanics behind some of the FSW interactions […]

Read More

Interested in Friction Stir Welding? Check This Out!

Since its invention in 1991 by The Welding Institute (TWI), Friction Stir Welding (FSW) has been predominantly used for welding aluminum alloys and other soft metals; however significant research over the past decade has enabled the FSW of high melting temperature materials such as steel, titanium, and nickel alloys. FSW is considered a green process […]

Read More