DMC2011 is coming up in Anaheim the week after Thanksgiving. I’ll be presenting in the Tuesday afternoon session on metals joining, along with others from EWI.

I’ll be presenting on trimodal aluminum and how to modify its properties with friction stir processing. I know that that is quite a mouthful. The nice thing is that the aluminum material gets a combination of high strength and reasonable elongation that can be localized where elongation is needed.

The trimodal aluminum is a metal matrix composite that is made by powder metallurgy. The three modes are from two processing routes for aluminum 5083 alloy and the addition to one of then of a hard ceramic material, boron carbide. This combination can be forged or otherwise rearragned to make plate parts.

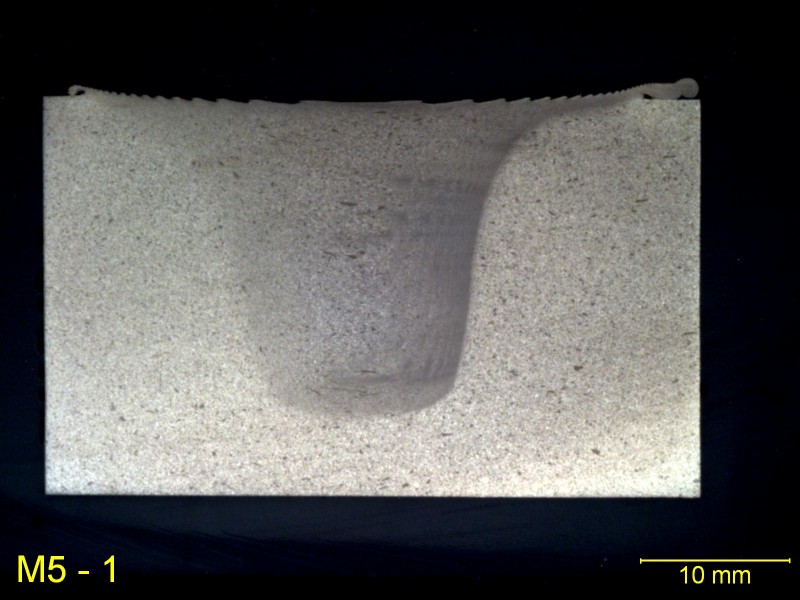

You can see below a one-pass example of friction stir processing of the material. A milling tool is run through the material at a set of parameters taht allow the material to re-consolidate behind the tool.

The friction stir processing does its magic by modifuying the grain sizes and orientations in the region that had to flow to get out of the way of the tool.

You can check with me at [email protected] to get more information on what’s going on at DMC2011 or information on the ways that trimodal aluminum can be valuable for structures.