Wire DED (Directed Energy Deposition) processes have come a long way. Over the last 10 years, there has been a lot of interest, particularly in process parameter development and in-situ monitoring.

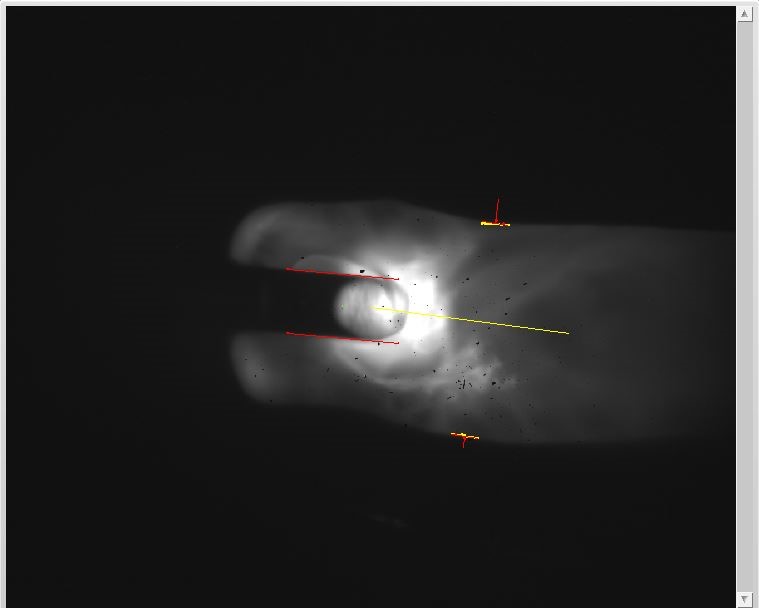

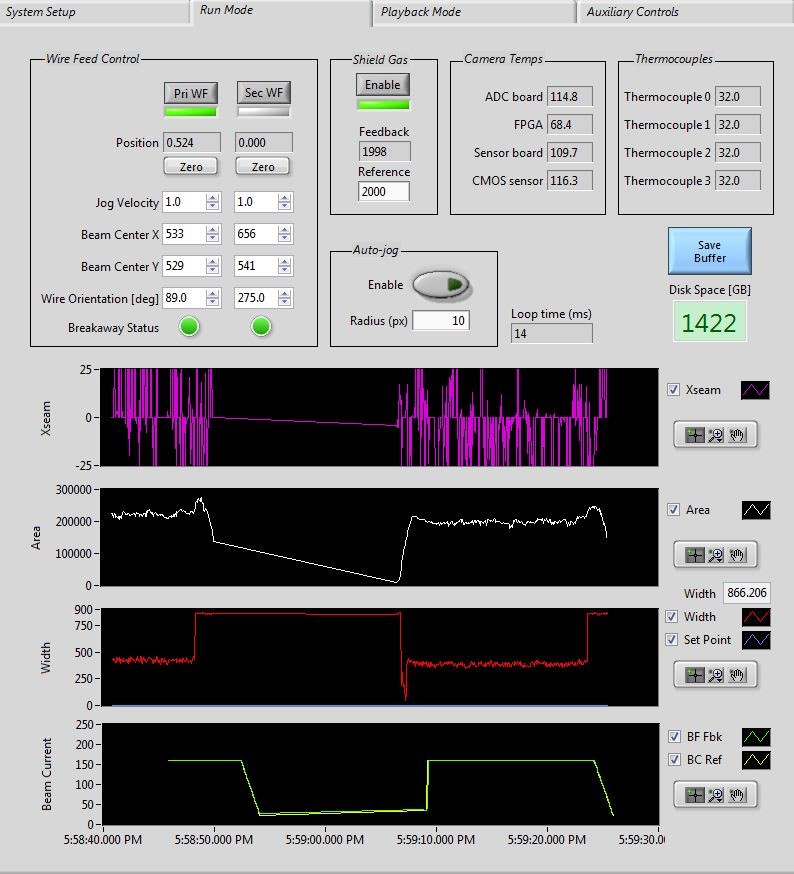

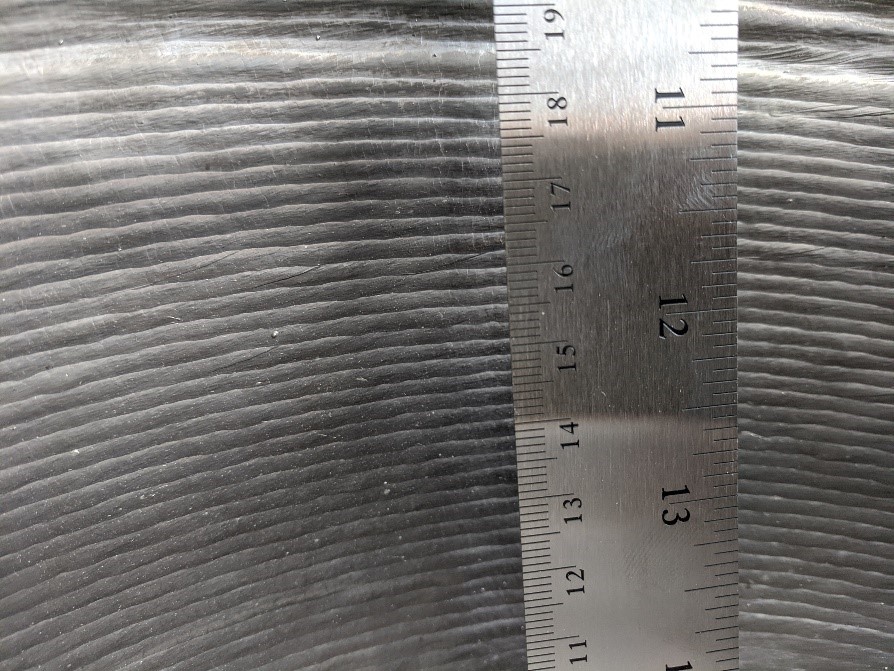

At EWI, we are is monitoring and controlling every detail (like seam, melt pool, heat-input etc.) to make sure process remains stable (see pictures), and at the same time the resulting properties are acceptable. Our systems can build large scale components with deposition rates as high as 25 lbs/hr (~12 kg/hr) out of most of the materials like Ti64, Inconel 718, 625, Alloys steels, Aluminum alloys, etc. thereby reducing build time.

To learn more about wire DED at EWI, contact Dennis Harwig at [email protected].

For information about EWI’s additive manufacturing capabilities and services, click here.