Polymer Science and Engineering

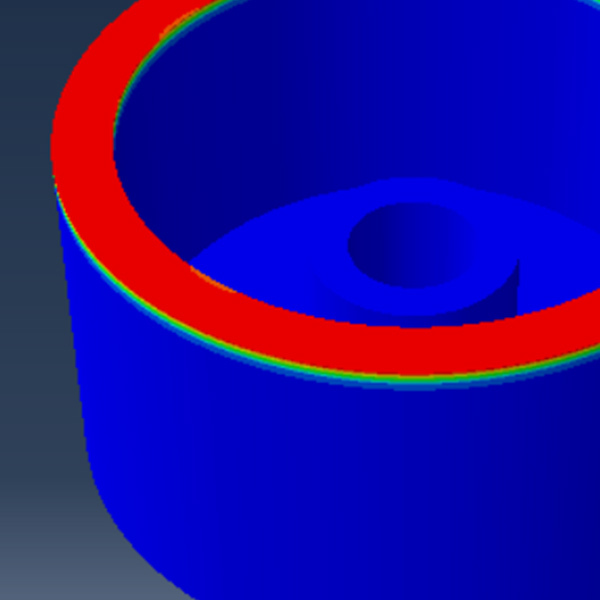

Improve design for manufacturing with plastics, optimize polymer materials selection and streamline production processes.

Using plastics in manufacturing can add versatility to an application, yet these materials can be tricky to characterize, test, and implement in new ways. A knowledgeable partner in materials science and engineering can go a long way toward developing successful plastic manufacturing solutions. Partner with EWI for polymer processing expertise that confirms manufacturability from the start.

The EWI polymers group has deep expertise in thermoplastics, thermosets (adhesives and rubbers), carbon-based materials, and polymer-based composites. We work in every stage of the product design cycle, including material selection, design, testing, aging, joining, failure analysis, and solutions implementation.

Access EWI’s polymer engineering experience and lab capabilities to introduce products to the marketplace with full confidence and controlled costs.

See examples of EWI’s R&D work in polymer characterization, qualification, and evaluation:

- New Way of Testing Hydrogen Permeation in Polymers

- Advanced Joining Process for Thermoplastic Composites

- Predicting Polymer Service Life through Degradation Modeling

- Deterring Material Failure in Plastic Medical Products

- Diagnostic Tool for Surface Contamination on Ultrasonic Welds

- Effects of Pressurized Hydrogen on Polymer Elastomers

Plastic Materials Science at Its Best

EWI’s comprehensive understanding of polymer properties – physical, mechanical, thermal, chemical, time-dependent, degradation, and processing – can help you approach tough tasks like polymer joining involving transparent or dissimilar materials.

Think of us as your partner in researching and developing manufacturing solutions involving diverse and mixed materials and brand-new processes. While the modern polymer material science lab is well-equipped on its own, it’s even more robust when paired with the capabilities of EWI’s metal materials science lab, hydrogen test lab, and other cross-disciplinary teams and facilities.

Bring us your polymer-related challenges, and we’ll get started on solutions.