So I’m not what you would call a handy person around the house and I generally pass on home projects unless forced to act. In fact I pretty much epitomize the quote “If a man says he will fix it he will. There is no need to remind him every six months about it.”

Now wouldn’t it be great to be able to remove all the old paint almost instantly? For the common man, that’s the idea of EWI’s laser paint stripping technology.

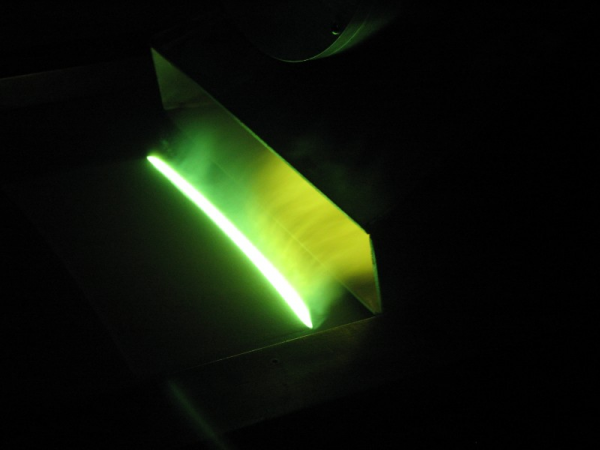

Stan Ream and the EWI Laser Technology team at EWI have developed world leading expertise in the use of lasers for welding, cutting, drilling, and other applications. Key to this is the ability to control precisely shape and motion of the laser beam. In developing this know-how, it was theorized that we could use this knowledge to scan the beam quickly and broadly to remove substances from a surface. The first prototype, developed using internal funding, was put together using many novel innovations in order to prove out the concept. In this early video, you can see just how successful it was. The paint is rapidly combusted and exhausted into the vacuum. The process is so quick that the underlying material does not get hot to the touch either… And yes… There is a Toro leaf blower wired in reverse to remove the paint fumes.

Now why is this technology important? Because current methods of removing coatings or contaminates may involve chemicals (environmentally unfriendly), involve putting contaminates in the air, or at the minimum a lot of time. Imagine how long it must take to sandblast a simple water tank (between set-up, process time, and clean up) or the time to remove paint from an airplane using a similar method. As you see in this video demonstration, EWI was able to show how effective and precise this technology can be on an aircraft part.

The Laser Paint Stripping technology is not limited to paint either. It has been contemplated that a device similar to this can be used to remove nuclear contaminants in reactor clean-up or as an efficient method to clean a wide variety of surfaces.

My goal would be to have it remove wallpaper prior to my next home project, but that’s probably a little selfish on my part.

If you have any questions about the variety of applications or some more technical inquiries, please contact Stan Ream at 614.688.5092 or Mark Schimming at 614.688.5139 or leave a comment below. Time may be of the essence, as Stan just completed building a Cobra replica from scratch that was just recently road certified, so speeding tickets and court dates may be occupying a bit more of his time come this spring.

For installment 3 of the manufacturing innovation for the common man series, I will highlight why you should care about friction (inertia and linear) welding. Leave me a comment if you would like me to profile another technology ([email protected]).