Ahead Of The Curve On US Manufacturing

So here’s the deal… I am SUPER excited that manufacturing in the USA is going through this “re-birth.” I think it’s great that one thing Congress and President Obama can agree on is the fact that we need to bring manufacturing jobs back to the US (not so awesome is the fact that this may […]

Read More

Robotic Vision Systems & End-of-arm Tooling Course

Robotic Vision Systems & End-of-arm Tooling Course EWI/Buffalo Manufacturing Works Buffalo, NY August 21-22, 2024 This two-day course offers an essential introduction to the more common end-of-arm-tooling options/applications and robotic vision systems. Geared toward technical professionals who want to broaden their understanding of automated options within fabrication settings of all sizes, the course covers basic […]

Read More

A Superior Way to Join Transparent Polymers

Optically transparent medical testing devices, such as microfluidic chips and diagnostic components, require precise and delicate welding techniques to maintain their functionality and integrity. The need for clarity and the intolerance of contaminates make most welding approaches unsuitable. Hot plate welding is too imprecise due to the need to move the parts during the joining […]

Read More

New EWI Course — Robotic Vision Systems and End-of-arm Tooling

EWI is pleased to announce a new addition to its slate of in-person automation classes, Robotic Vision Systems and End-of-arm Tooling. This two-day course offers an essential introduction to some of the more common end-of-arm-tooling (EOAT) options as well as applications and robotic vision systems. Structured as a functional overview for technical professionals who want […]

Read More

Robotic Vision Systems & End-of-arm Tooling: An Introduction

Robotic Vision Systems & End-of-arm Tooling: An Introduction April 2-3, 2024 EWI/Buffalo Manufacturing Works, Buffalo, New York The Robotic Vision Systems & End-of-arm Tooling course offers an essential introduction to some of the more common end-of-arm-tooling options and applications and robotic vision systems. Structured as a practical overview for technical professionals who want to broaden […]

Read More

Robotic Vision Systems & End-of-arm Tooling: An Introduction

Robotic Vision Systems & End-of-arm Tooling: An Introduction February 27-28, 2024 – SOLD OUT EWI/Buffalo Manufacturing Works, Buffalo, New York The Robotic Vision Systems & End-of-arm Tooling course offers an essential introduction to some of the more common end-of-arm-tooling options and applications and robotic vision systems. Structured as a practical overview for technical professionals who […]

Read More

EWI’s Green Laser Capability for Electrification, Copper Welding, and DED

EWI’s Green Laser Capability for Electrification, Copper Welding, and DED By Jacob Hay The use of industrial lasers for manufacturing has been gaining popularity for decades as laser sources have improved in efficiency and reliability. A properly selected laser energy source combined with the right system can offer great flexibility, providing varying energy densities, wavelengths, and […]

Read More

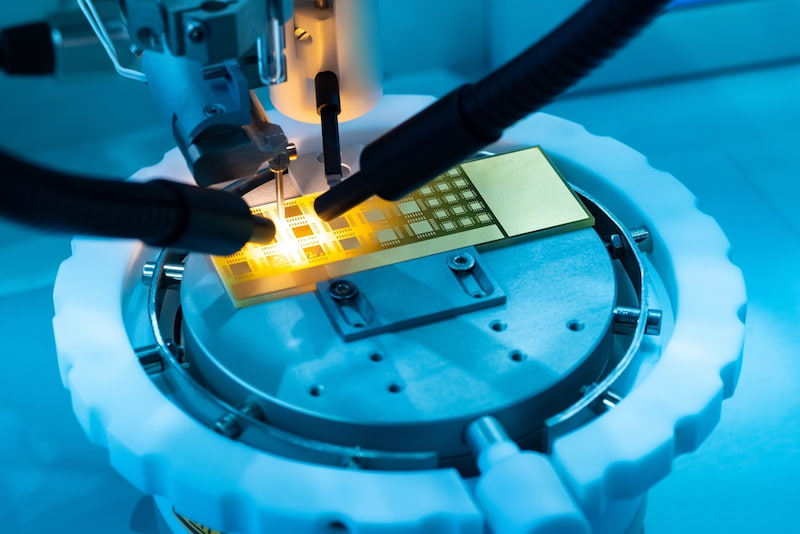

Consumer Electronics

Success in consumer electronics manufacturing requires tight design-to-market timelines, streamlined production processes, and minimized costs. Understanding the interdependencies of these elements can make or break a new product. EWI helps companies develop consumer electronics manufacturing solutions and efficiently adopt them. We apply our cross-industry experience and process expertise to address your unique challenges in complex […]

Read More

Gas Metal Arc Welding Basics, Part 2: CTWD and Travel Speed Variables

Part 1 in our GMAW series, Gas Metal Arc Welding Basics, Part 1: Welding Current and Voltage, discussed how variations in both welding current and welding voltage affect the penetration profile and bead profile of a weld. In this installment, the variables of travel speed and contact tip to work distance (CTWD) will be discussed […]

Read More

Predicting and Avoiding Crack Formation in Directed Energy Deposition

Common aerospace materials such as high-nickel alloys (such as René 80) or high-strength aluminum alloys (6000 and 7000 series) are not currently manufactured using additive manufacturing (AM) due to hot cracking. As part of a $5M Department of Energy program, EWI, GE Research, and the University of South Carolina developed a model to predict and […]

Read More