What you need to know about Friction Welding Processes

Friction has been used to weld parts for both new make and for repair for many decades. The friction welding family of processes encompasses many different variants, including rotary friction welding (inertia, direct-drive, and radial), linear friction welding, and more recently, friction stir welding (FSW). In each case, friction heats the material to a plastic […]

Read More

Meet the EWI Arc Welding Team – Nick Kapustka

This installment of “Meet the Team” features Nick Kapustka. Nick is a bright young engineer with experience in aerospace applications and non-ferrous materials. Please don’t hesitate to contact Nick if you have any questions or interests related to EWI or Arc Welding. You can reach him at 614.688.5000 or [email protected]. Technical Expertise Nick Kapustka is […]

Read More

Meet the EWI Arc Welding Team – Randy Dull

This installment of “Meet the Team” features Randy Dull. Contrary to his name, he is a quite personable fellow that is very knowledgeable with all things arc welding. Please don’t hesitate to contact Randy if you have any questions or interests related to EWI or Arc Welding. You can reach him at 614.688.5095 or [email protected]. […]

Read More

Why Size Matters When Friction Welding

My colleague, Tim Stotler, gave a very good overview of friction welding here. Go ahead, click the link… you know you want to! Just don’t forget to come back and finish reading my blog. In his write-up, he touches on the variety of components that are commonly friction welded in industry (hydraulic cylinder rods, aircraft engine […]

Read More

Returning from FABTECH 2015 – An EWI Associate’s Perspective

FABTECH is always an information-packed meeting for me. This year, advances in computer technology and information sharing capability was a strong theme with equipment suppliers. New types and improvements in welding consumables were also noteworthy. Welder training devices, including a couple that EWI helped to develop, were drawing crowds in several booths. EWI engineers had […]

Read More

Fabrisonic’s Board of Directors Names Jason Riley as Chief Executive Officer

Fabrisonic, the world’s leader in ultrasonic additive manufacturing (UAM), has announced Jason Riley as Chief Executive Officer, following Mark Norfolk’s retirement after nearly 14 years of leadership. Jason Riley has served as Fabrisonic’s Chief Operating Officer since 2021. UAM is a hybrid (additive & subtractive) metal manufacturing process that employs solid-state welding to join dissimilar […]

Read More

Consumer Electronics

Success in consumer electronics manufacturing requires tight design-to-market timelines, streamlined production processes, and minimized costs. Understanding the interdependencies of these elements can make or break a new product. EWI helps companies develop consumer electronics manufacturing solutions and efficiently adopt them. We apply our cross-industry experience and process expertise to address your unique challenges in complex […]

Read More

Medical Devices

In medical device manufacturing, shrinking development timelines and budgets are at odds with simultaneous requests for improved product performance and functionality. How can you get your products to market faster and more reliably? EWI’s expertise in manufacturing technology for medical products includes battery development, welding of dissimilar and unique materials, polymer processing, nondestructive testing, and […]

Read More

Industrial Equipment & Heavy Manufacturing Sectors

Explore the primary sectors where EWI applies our heavy industry engineering and materials science expertise. We’re dedicated to helping manufacturers streamline processes, test materials, and develop technologies in the most efficient ways possible. Shipbuilding EWI has decades of experience in materials engineering and advanced shipbuilding technology innovation for both commercial and defense manufacturers. Our deep […]

Read More

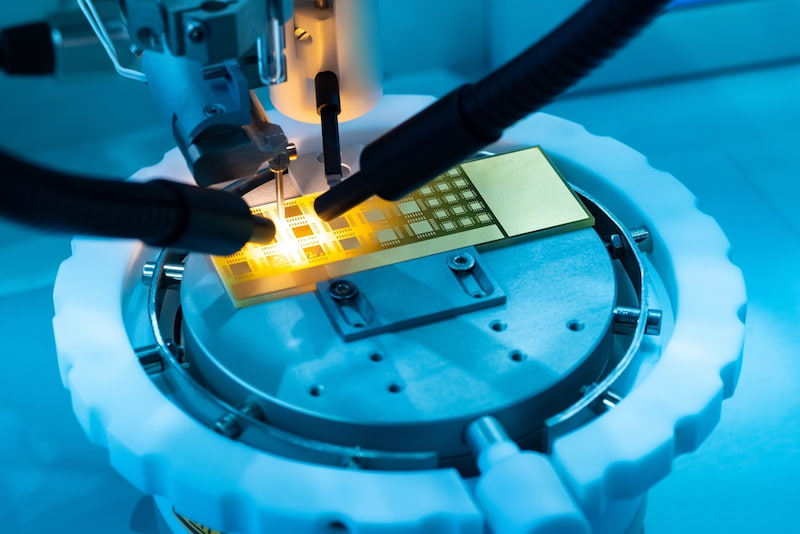

When Smaller is Better: EWI’S Microjoining Capabilities

Microjoining encompasses techniques including welding, brazing, soldering, and adhesive bonding. Typically, the technology involves materials with thicknesses less than 0.5 mm. Micro-welding techniques can be applied to join both similar and dissimilar materials combinations. Here are some key applications of microjoining today: For over 30 years, EWI has been developing and applying microjoining technologies to […]

Read More