No More Mess: Bonding Plastic to Metal without Adhesives

By James Cruz, EWI My first job out of college at Honda of America Manufacturing was a dream come true—the chance to play with robots and build cars! They handed me several crisp, white uniforms on day 1. Within that first week on the production line, however, I had soiled my pretty white pants with a huge, […]

Read More

FABTECH 2022 and the AWS Professional Program

EWI WELCOMES YOU TO FABTECH 2022! WHAT’S YOUR CHALLENGE? Having difficulties welding dissimilar materials? Trying to achieve higher productivity in your welding process? Evaluating the weldability of a new alloy? Do you know what welding process you should use? EWI CAN HELP! Visit us at Booth C-13101 in the Welding Pavilion (Hall C). EWI CAN […]

Read More

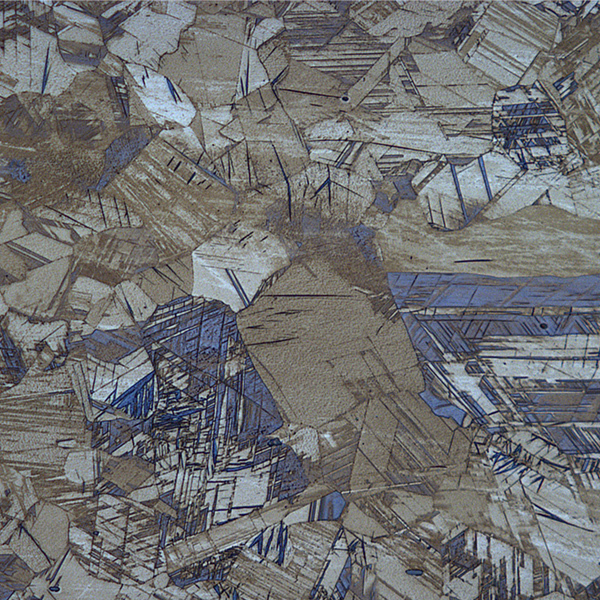

Metals & Metal Matrix Composites

Metals & Metal Matrix Composites The materials engineers at EWI have been providing services to characterize and evaluate metals for more than 35 years. As new metal alloys and metal matrix composites are developed, manufacturers across all sectors have routinely turned to our team to assess feasibility for use in their applications. Our specialty areas […]

Read More

Polymer Science and Engineering

Improve design for manufacturing with plastics, optimize polymer materials selection and streamline production processes. Using plastics in manufacturing can add versatility to an application, yet these materials can be tricky to characterize, test, and implement in new ways. A knowledgeable partner in materials science and engineering can go a long way toward developing successful plastic […]

Read More

Aeromat 2021

Aeromat 2021 May 24-26, 2021 A Virtual Event Four EWI associates will be presenting this year at Aeromat 2021: Putting Materials and Process Research to Work: Transitioning from the R&D Lab to Application — Ron Aman, Principal Engineer, Tuesday 3/25 at 10:00 am. Relation of Surfact Texture and Surface Finishing with Design of Additive Manufacturing […]

Read More

Prediction Capability for Laser-welded Blank Formability

Laser welded blanks (LWBs) are produced by laser welding two sheet materials together, typically prior to a forming process. The sheet materials can be identical or dissimilar depending on the application. The LWB process allows the designer to ‘tailor’ the location of the desired material properties in the blank for crashworthiness and lightweighting. LWB technology was […]

Read More

Many product recalls stem from predictable material issues

Choosing materials for a new medical device or consumer product is not a trivial task; without proper care, costly late-stage issues can derail an entire program. Material failures for medical devices, for example, are common and costly; 30-40% of FDA recalls are due to material issues.1 These issues may include compatibility of the fluid formulation […]

Read More

EWI and MTI to participate in DOE research project on material joint reliability

The U.S Department of Energy (DOE) Office of Fossil Energy (FE) and the National Energy Technology Laboratory (NETL) recently selected projects to receive cost-shared R&D under the opportunity announcement (FOA) DE-FOA-0002192, Extreme Environment Materials for Power Generation. One of the projects selected is Robust Dissimilar Metal Friction Welded Spool for Enhanced Capability for Steam Power […]

Read More

Large-Scale Additive Manufacturing

The demand for large-scale additive manufacturing (LSAM) is rapidly growing, as this process allows large products and parts to be produced more quickly and efficiently. Different from 3D printing, this type of product manufacturing produces industrial, large-scale components. Newer to mainstream manufacturing, large-scale additive manufacturing builds products and components faster and more efficiently than ever […]

Read More

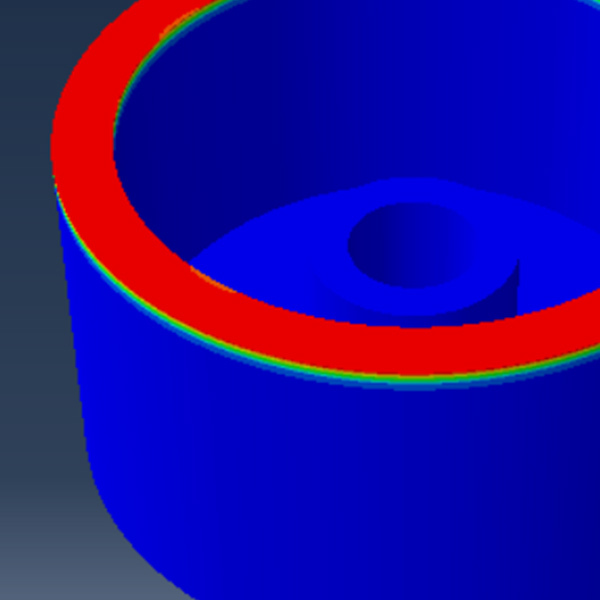

Optimizing Ultrasonic Knurl Patterns with FEA

Electric vehicles and consumer electronics depend on high-capacity, highly efficient batteries, and the demand continues to rise. Critical to producing these batteries is the successful welding of foil-to-tab joints which are often made of dissimilar materials with dissimilar thicknesses. This process is complicated, and the failure of a single joint will compromise an entire battery […]

Read More