NDE & Inspection

EWI stands at the forefront of advanced NDE techniques.

We apply state-of-the-art equipment, innovative methods, and advanced mathematical modeling to facilitate inspection and assessment of complex materials and components.

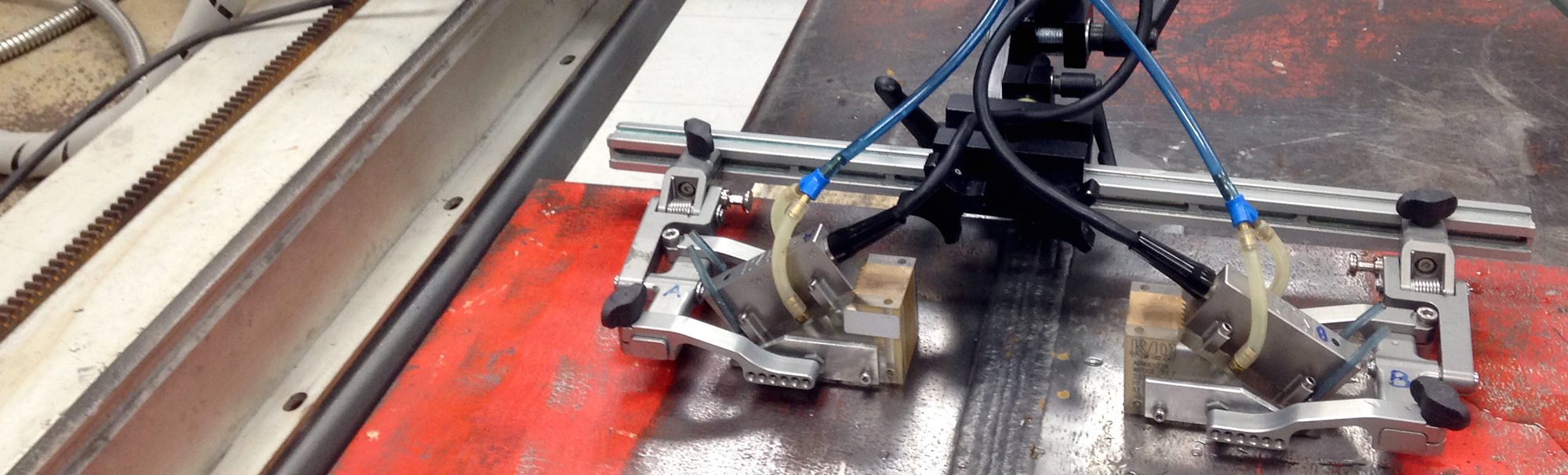

EWI’s Nondestructive Evaluation (NDE) group designs and develops inspection technology for a broad range of applications. We use manual and automated inspections, custom equipment designs, and mathematical modeling to tackle the most challenging inspection problems. In addition to weld evaluation, we develop procedures to inspect bulk materials and components. We continually update our capabilities to include state-of-the-art NDE techniques and work closely with EWI’s other technology groups to assure the highest standards of quality.

Innovations

DEVELOPING INSPECTION PROCEDURE AND INSPECTING oxygen- free copper conductors used to upgrade the National Spherical Torus Experiment (NSTX), a magnetic fusion devise used to study spherical plasmas at the Princeton Plasma Physics Lab (PPPL).

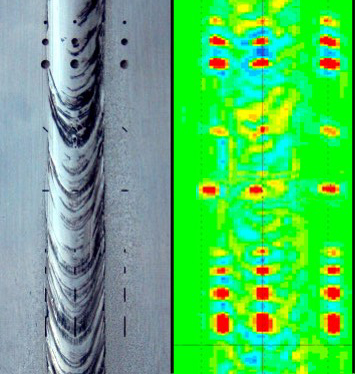

THE DEVELOPMENT OF THE SPOTSIGHT™ SYSTEM, an ultrasonic instrument used to nondestructively evaluate resistance spot welds. By combining OEM hardware, custom software, and advanced packaging, EWI created a hand-held device that is commercially available today (Progenero Products). Using the same technology, a flexible, automated system is currently being developed for integration onto factory floors at OEMs and Tier 1 suppliers.

THE CREATION OF A LASER INSPECTION PROCESS FOR PIPELINES IN THE OIL AND GAS INDUSTRY. Using laser topography to scan the internal weld of the pipe with a pigging system eliminates many of the problems of nondestructive evaluation methods, such as the high false positive rate. EWI has now produced nearly 20 units, which use a laser scanner, three motorized axes, and a video camera, allowing the operator to rotate the video camera freely. The entire process of lining up the pig, scanning, and analyzing the results can be completed in a few minutes.

Identify.

Develop.

Implement.

WE MANUFACTURE INNOVATION.

When you engage with us to solve your inspection challenges, you get the support of every EWI expert with applicable capabilities from across our multi-disciplinary working groups, including materials engineering, modeling, laboratory testing, and optics design.

Achieve consistency and reliability in your products.

Develop and implement in-process and post-process inspection solutions that will reduce waste, save time, and improve the quality of your product. EWI is ready to help.

View NDE & Inspection Resources

Technical Expertise

EWI’s NDE group boasts industry-leading expertise in phased-array ultrasonics and array eddy current. We are currently expanding our capabilities into the areas of full matrix capture (FMC) and computed tomography (CT). As materials joining and forming techniques evolve, so does our ability to inspect both bulk materials and completed joints.

- Inspection of arc, friction, ultrasonic and resistance welds

- Inspection of ferrous, nonferrous, polymeric and ceramic materials

- Inspection of additively manufactured materials

- Rail inspection

- Pipe inspection

- Automated inspection systems

- Laser-based ultrasonics for non-contact high speed inspection

- Microwave-based NDE for nonmetallic materials

- Ultrasonic, Eddy Current, X-Ray and CT mathematical modeling and simulation

- Quantification of NDE performance through comprehensive probability-of-detection and sizing accuracy studies

- 2D and 3D finite element analysis for eddy current NDE methods

- Thermography

- Radiography

- Computed Tomography (CT)

- Advanced ultrasonic inspection including phased-array, full matrix capture with total focusing method, and time of flight diffraction techiques

Equipment & Lab Resources

- Linear and 2D Matrix phased array ultrasonics

- Ultrasonic-induced thermography and conventional thermography

- Electromagnetic acoustic transducer (EMAT) based ultrasonics

- Inter-digitized transducer (IDT) based surface wave ultrasonics for surface flaw and damage detection

- Array eddy current with imaging capabilities

- X-ray radiography and computed tomography (CT)

- Nikon XTH225

- Nikon XTH450

Learn more about our NDE & Inspection capabilities

Contact our experts for more information